Bajaj – Continental Machinery

Leading Manufacturers, Exporters, Wholesaler, Retailer of Ginning Machinery, IMPCO-Delinting and Acid-Delinting from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weight | (5670 Kg) 12,500 Lb. |

| Extractor-feeder Motor | 15 Hp, 1800 Rpm or from Gin (not Included with Machine) Saw Shaft |

| Feed Motor | 3/4 HP, 1800 RPM, 230/460 volt, 3-phase 60 Hz, TEFC Frame 56C (wire for 230 volt) |

| Gear Reducer | Grant, 30:1 Ratio, Stf 225 Worm Gear W/standard Length Shaft |

| Four Saw Cylinders | 16 1/2″ Od, 95 5/8 Long, 160 Saws 5/8″ Wide |

| Two Doffing Cylinders | 11 5/8″ Od, 95 5/8″ Long |

| Two Feed Cylinders | 5 3/4″ Od, 95 5/8″ Long, 6 Vanes |

| Four Spiked Cylinders | (ls-1) 110 Volt, 30 Mm, 3/16″ Sensing Distance, Led, 9 Sec. Start Up Delay |

| Length Inside | (2438 Mm) 96 In. |

| End of Shafts | (3276 mm) 129 in. |

| Overall (with covers) | (3657 mm) 144 in. |

| Height | (2337 mm) 92 in. |

| Width : Front to Back Rear Doors Closed | (2426 mm) 95 1/2″ |

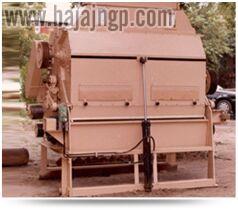

Designed for improved fine trash removal and enhanced single locking. This BAJAJ CONEAGLE Golden Eagle feeder has shown superb test results in all areas of its application. The Model 9000 is the result of an extensive research and development program and on-site testing.

A push-button control panel, mounted on the feeder, controls feeder load or ginning rate and may also be operated from the master console. This panel contains eight annuciator lights for indicating status of the ginning operation. An AC inverter drives the 3/4 hp feed motor for ease of control and operations. A dual set point meter controls capacity of inning through current load on the gin motor. The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner automatically stop the ginning operation if the cotton flow is interrupted. The standard drive for the Model 9000 is a 15 hp, 1800 rpm motor*.

Flow of Cotton

As seed cotton enters the Model 9000, it is first exposed to four spiked cleaning cylinders. The cotton passes over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking. These spiked cylinders are the same type as used in our 96″ BAJAJ CONEAGLE Impact Cleaner.

Once through the inclined grid section, cotton is carried to four 16 ½” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through the tested combinations of brushes, control bars and grid sections allows for excellent hull, stick and additional fine trash removal and further enhances the opening of seed cotton locks for improved ginning. Two doffing cylinders transfer the seed cotton from cleaning cylinders to the feeder apron.

Maintenance Considerations

Lockable, hinged fiberglass covers provide a clean design while allowing access to drives, bearings and adjustment points. The covers need only be opened, not completely removed, for repairing cylinders and other components. Segmented heads allow each cylinder to be removed independently without completely disassembling the machine.

Other features include 5 ½” glass windows in the heads to aid adjusting brushes, grids, control bars and doffers. Two full width rectangular windows on front of the feeder allow viewing the flow of seed cotton.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Brand Name | Bajaj |

| Type | Seed Cleaning Machine |

| Country of Origin | India |

| Fan Motor | 10 HP |

| Motor for Sieve Boat | 3 HP |

| Screen Size L*W | 800 * 1500mm |

- Quick assembly of attachments

- Designed for higher safety

- User friendly

- Handling big loads

We offer custom designed attachments for material handling by tractors in cotton ginning and pressing plants. Bajaj employs latest design techniques and manufacturing techniques to provide rigid, high quality attachments for

- Cotton Bale Handling

- Loose cotton handling

- Seed Heaping and loading to bagging hoppers

- Heaping of cotton

FEATURES & BENEFITS

- Heavy duty applications

- Anti friction bushes and high quality hardened pins at all points

- Robust construction for long life

- High quality hydraulic systems for better performance

- Level indicators available wherever necessary

- Bucket sizes as per customer’s requirements

- Easily detachable units

- Lifting heights upto 17 ft.

- Non metallic coverings for tips to avoid chances of spark or fire

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Continental Eagle Corporation turned a page in its long and storied history today when it was announced that the manufacture of cotton gins and related machinery in its Prattville, Alabama plant will be phased out over the next year, after more than 177 years of continuous operation in Prattville.

Roger Fermon, the President of Continental Eagle, made the announcement to the company employees today, stating that the manufacture of nearly the entire product line will be transferred from its historic Prattville facility to Nagpur, India. Nagpur, located in central India, is the home of Bajaj Steel Industries, Ltd., a well established and highly respected manufacturer of cotton ginning machinery. Mr. Fermon stated, “Like Continental Eagle Corporation, Bajaj is the leader in their segment of the industry and they are a natural fit as our partner to continue the tradition of producing the highest quality ginning machinery in the world.”

Earlier this year Continental contracted with Bajaj to manufacture a limited portion of the product line at their plant in India. “The transfer was very smooth and the quality was excellent”, said John Kolasky, Vice President of Engineering at Continental. “An independent contract engineer confirmed that the quality and capacity was every bit as good as the machines made here.” To assure that the quality is maintained, Continental will permanently assign a quality control engineer to oversee the manufacture in India and engineers from Continental will make regular visits. “To maintain and increase our customer base, we cannot compromise on quality. Our customers should expect no less,” says Kolasky.

The corporate headquarters in Prattville will retain some light manufacturing for repairs and for a small number of items such as gin saws. Continental has developed a reputation for supplying the best gin saws in the industry

Bajaj has begun construction of a new facility to handle the increased volume. They operate the most advanced computerized machinery in their factory. The skill level and work ethic of their engineers and factory personnel is exceptional. The Continental equipment will not be modified to metric measure. All machines and parts will continue to be built to US standards to maintain continuity of parts for the installed base and for future customers.

“Bajaj was not the only company in contention for this partnership, but they emerged as the obvious choice after our successful experience with them on the pilot program earlier this year. There is no language barrier and the technical communication between our engineers is very efficient,” says David Mrozinski, Vice President of International Sales. “Not just any company was considered. We have been acquainted with the Bajaj family for many years and we know them to be very professional, well organized and of the highest integrity. Their existing product line has, by far, the largest share of that segment of the market. They do not compete with Continental products. We will in fact, compliment and enhance their product offering in the Indian market.”

“We are excited about the new direction our company is taking,” continued Mrozinski. “We will supply our parts and machinery to the cotton industry more competitively, while maintaining the same quality that has always been expected of Continental Eagle products and services. It also allows us to penetrate markets that have been unapproachable in the past.”

Continental Eagle Corporation will continue to operate out of Prattville, but on a different level and with a revised business model. “We will operate primarily as a marketing and engineering firm, maintaining our expertise in machinery design and distribution of our products to the cotton industry,” says Fermon. “Our spare parts sales and after sale service as well as our research and development will remain here in Prattville. Our branch offices throughout the USA and in Australia will continue as they have in the past to service our customers.”

“The extended downturn in the cotton industry here in the United States and throughout the cotton growing regions of the world combined with significant raw material cost increases have caused us to review our corporate structure and the direction we will take the company,” said Mr. Fermon. “Orders of machinery and systems have declined over the past few years, but we did not see a reduction in market share. Our customers are cutting back and waiting for improvements in the industry and in the global economy. We have had to lay off many of our factory and office personnel to maintain the company during this low period, as have our competitors.

Fermon went on to say, “In order to respond to these new market developments, we had no choice but to increase our sales through an increase of our market share. To reach that goal we decided to combine our proven Research and Development talents with quality manufacturing, but at a lower cost. The most recent results of our Research and Development efforts were the very successful introduction this year of our new EagleMax 201 saw gin and the EagleMax 9120 feeder. Continental Eagle will be able to continue to provide the latest technology at a lower cost while still maintaining its recognized high standard of quality.”

Continental Eagle is an American owned, US corporation and will remain 100% controlled by the existing owner. All proprietary technology will be retained by Continental Eagle Corporation and Bajaj will function solely as a supplier under the supervision of Continental.

“These changes will free us to concentrate our efforts toward continuous improvement of supply and customer service without the pressures imposed by a widely fluctuating market and escalating material costs,” says Mr. Fermon. “By combining our design experience and our extensive knowledge of the cotton markets with the manufacturing capabilities of Bajaj, Continental Eagle will continue to provide the world class parts, machinery and systems for which we are recognized. We look forward to serving the cotton and oil mill industries for many years to come.”