Bajaj Ginning & Pressing Machinery

Leading Manufacturers, Exporters, Wholesaler, Retailer of Ginning & Pressing Machinery, Baling Presses for Other Applications, Cotton Seed Delinting Machine, Mechanical Conveyors & Elevators, Humidification Systems, Engineering & Costruction Projects, Dust Waste Handling Systems and Bajaj Components & Machine Part from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Application | Cotton Ginning |

| Country of Origin | India |

| Material | Mild Steel |

| Brand | Bajaj Steel |

| Model | Tejas |

| Rotation of Machine Pulley | Clock Wise |

| Gear | Helical |

We have been awarded the “Largest and modern cotton ginning & pressing machinery manufacturer in India” by the hands of then Hon’ble Union minister of textile Govt. of India Mr. Shankersinh Vaghela.

Bajaj DR gins give highest out turn of lint with better seed quality at lowest maintenance and per unit cost of production. Similarly high efficiency Bajaj down packing cotton baling press produces highest number of bales at lowest cost per bale. We offer complete cotton ginning, pressing, cleaning, conveying and handling solutions and turn key ginning and pressing plant machinery.

Why Tejas DR ?- Increased leather roll diameter

- 16 sealed / Pre greased bearings

- Only 2 greasing points

- Robust Box type beater housing for easy setting

- Adequate weights on leather roll for higher production

- Maximum strength to Gin upto 50 G/Tex cottons

- Use of superior material for highest strength of spare parts

- About 50% lower vibration

- Improved Seed Channel Design

- Improved Hopper Sheet Design

- Powder coating on Auto Feeder Assembly

- Less Power Consumption per unit of production

- One to One replacement on Jumbo/ Super / Platina models

- Protects Fibre Quality ; Gives Production of Clean ; Lustrous Cotton Lint.

- Works efficiently ; reduces cost and Adds to profitability.

- Engineering experiences and expertise combined to ensure lowest operational and maintenance cost.

- Consumes less power.

- All gears, connecting rod, head, beater arm, swing lever etc. are made of high Nodularity ductile iron.

- All rotating parts are provided with precision bearings to reduce friction for optimum efficiency.

- Connecting housing is provided with heavy duty self aligning roller bearing.

- Leather roller shafts are interchangeable and if one side of the roller is worn out, It can be reversed.

- Lint output remains uniform on full length of the rollers.

- Moving parts are housed in dust proof gear box for smooth running.

- Lubrication is pressure fed, dust proof greasing system.

- Special hardened bushes for weight levers and swing levers to ensure smooth working of gin.

- Over 55,000 gins are in efficient operation in India & Abroad.

- Fully backed by after sales services, provided by team of trained and Competent engineers.

- High quality replacement parts and spares available at all times.

- Lowest power consumption per quintal lint ginned

- Fully machined fly wheel / machine pulley

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish & Tolerances to provide enhanced life of the machine & lowest down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Brand Name | Bajaj |

| Feed Opening | 30”L X 30”W |

| Box Size | 48”L X 30”W X 30”H |

| Operating Pressure | 2700 PSI |

| Finished Bale Size | 55”L X 30”W X 30”H |

| Stroke Cycle Time (No Load) | 20 seconds |

| Power Consumption | Aprox 40 HP |

| Weight of Machine | 3.5 Tons approx. |

| Overall Dimensions of Machine | Length 4650 mm / Width 1345 mm / Height 2165 mm |

| Bale Ties Required | 4 No’s |

| Operating | By PLC Panel |

BAJAJ HORIZONTAL BALING PRESS with a 40 HP Hydraulic Power Unit and a standard operating pressure of 2700 PSI and a 7-inch bore Industrial Grade Compression Cylinder is a unique solution for baling of various items such as bio mass, textile waste and many other applications. The Model has the advantage over other similar baling presses as compression force is higher by about 36%, which yields up to 40% heavier bales. Bale tie required per bale is 25% lesser and hence 25% lower baling material cost. The other models for higher or lower pressure are also available on request.

FEATURES & BENEFITS FOR HIGH & MEDIUM CAPACITY PRESSES

- Highest bale density of all similar machines.

- Largest feed hopper of all similar machines.

- Feed hopper door with inspection windows, dust seals and interlock.

- Heavy duty spring loaded retainer dogs.

- Level sensor at hopper for automatic operation of main ram.

- Warning for startup and full bale.

- Double tie slots in ram to prevent material buildup and also crossing of bale ties.

- Adjustable bale density switch.

- Robust Body

- Simple Operations

- Easy Maintenance

- Highest Bale Density

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Industrial |

| Country of Origin | India |

| Brand | Bajaj |

| Material | Stainless Steel |

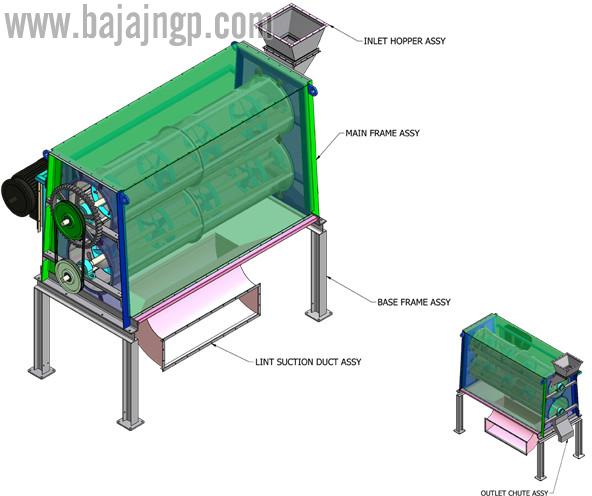

| Brush Motor | 3 hp - 1000 / 1200 rpm |

| Saw Motor | 40 hp - 1450 / 1750 rpm - 380/ 230 - 460 v / 3 ph / 50 - 60 hz |

| Overall size | 2.8 m x 1.5 x 3.1 – excluding feed hopper |

| Connected motor | 40 HP |

| Production Capacity | 500 to 800 kg/hr – depends on linter % |

| Suction fan motor | 50 HP |

BAJAJ BRUSH DELINTER is designed specially for cottonseed breeding & black cottonseed producing industry. This machine is a gentle delinter which can remove up to 80 to 90% of the linter available on the cottonseed. The machine deploys rotary brushes and abrasive strips to provide superior delinting action.

Bajaj Brush Delinter

- Built with counter directional drums & brush

- Drums coated with abrasive for superior quality delinting

- Gentle rotary speeds which minimizes seed damage

- Two stage delinting in one machine

- The machine is tailor made for seed breeding industry

- One common motor for two drums

- The machine is optimally designed for lowest lint suction fan power consumption

The delinter machine with all other auxiliary machine is supplied as a turnkey solution for seed breeding purposes. The auxiliary machines include gravity graders, seed coating machine, seed bagging machine etc

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Shape | Rectangular |

| Usage | Moving Goods |

| Specialities | Long Life, Excellent Quality, Corrosion Proof |

| Country of Origin | India |

| Brand Name | Bajaj |

| Surface | Galvanized |

| Structure | Conveyor System |

- Available in various sizes upto 450 mm diameter

- Helicoids of high quality carbon steel provides smooth surface with no sharp edges.

- All rotating parts are provided with precision bearing to reduce friction for optimum efficiency.

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish and tolerances to enhance life of the machine & minimizes the down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

- Bearings are enclosed in bracket housing with dust proof covers thus enhancing the life.

- Troughs designed for optimum feeding and carrying of material to machine or for bagging.

- Reduces man power in the process largely.

- Robust Construction

- Long life

- Maintenance free

- Uniform and adequate feeding at all points

- Ease of use

- Protects fibre quality

- Made with superior technical know how

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Stainless Steel |

| Driven Type | Electric |

| Application | Humidifying Use |

| Country of Origin | India |

Feature

- Instant / Online humidification

- Increases bale weight

- Reduces pressing force

- Reduces power per bale

- Improves lint grade & appearance

- High quality construction for longer life

- Improves fibre parameters

Humidifiers with disel / gas / kerosene burner suitable for 1700 1700 CMH of hot humid air & 204 litres of peak evaporation capacity

Hot Air Humidification or Hot Air Moisture restoration in a cotton gin can have a huge impact on profitability. Some of the salient features are given below:

- nstant humidification by easing out wax surface of the fibre and recuperation after humidification by cooling effect for retained moisture.

- Preserves fiber length, improves strength and uniformity and reduces short fiber content.

- Eliminates moisture condensation which is a general problem with all other moisturisation techniques.

- Increases the lint slide capacity and allows more cotton to enter the press box at each stroke of the tramper and hence higher density bale is obtained.

- Improves the capacity of the bale press whereas dry cotton requires higher compression forces and more time to charge and compact it into the press box.

- Achives better sliding of lint in the lint slide.

- Hot humid air is inducted in the lint on a lint slide with a set of louvers at temperature around 45 to 50 Degree celcius.

- The hot air eases out the surface tension of the fibre and humidity is transfered to inner stem while air passes out. The cooling down recuperates the fibre surface and maximum moisture contents are retained by fibre for a longer period.

Our systems consists of :

Moist Air Generator: Humidifiers with disel / gas / kerosene burner

Moist Air Applicators: Lint Slide or Humidification Belt Conveyor

This is a unique device manufactured by Bajaj Steel Industries Limited in technical collaboration with M/s. Inc. USA. for moisture restoration in cotton lint applying psychrometric principles. It is a high temperature Humidifier for generation of Humid hot air free from water droplets. The vapour phase transfer of moisture at the diffuser assures controlled and positive enhancement of moisture content in lint to highest acceptable level, as per international standard. This reduces pressing force of bale press resulting in lower power consumption per bale and increases bale weight.

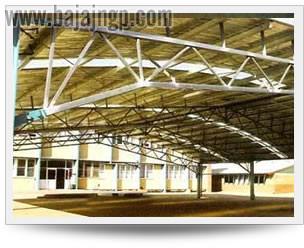

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Steel |

| Application | Space Truss,Industrial |

| Country of Origin | India |

| Feature | Corrosion Resistance |

| Surface Treatment | Polished |

| Position | Exterior |

Bajaj offers pre fabricated steel trusses for any projecs new or existing. Steel trusses are non-combustile, easy to handle, strong and easily fabricated for any design. these trusses are pre-engineered and pre-fabricated by truss experts available with us

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Dust Collecting |

| Country of Origin | India |

| Quality | Superior |

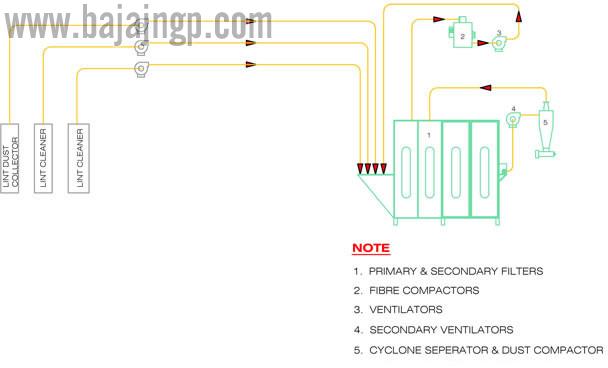

Dust / Waste Handling Systems particularly applicable to the handling of cotton / lint waste and associated trash created by machines in ginning plants. The system consists of a pneumatic ducting circuit connecting a filteration unit to all factory locations where waste and dust is generated. A fan creates an air flow in the ducting circuit to carry waste and dust therealong. The fan separates the air flow into major and minor portions and by centrifugal force transfers most of the waste and dust to the minor portion. The air in the major portion is directed back to the factory space via a filter to remove any dust contained in the major portion.

A typical waste handling system we offer for removing waste and dust from a ginning factory has been shown. The major components of the waste/ dust handling systems comprise of :

- Pneumatic ducting line with G.I. Pipes, bends and diverters.

- Centrifugal fans already attached to the systems in case of existing plants to draw dust / trash from the trash generating machineries.

- Primary filter to seperate fibrous material from the conveying air and allows micro dust to pass to the secondary filters.

- Secondary filter to seperate micro dust from conveying air.

- Ventilator to pull microdust air along with fibrous waste from primary filter to compactor and again supply the excess to primary filter after compaction.

- Secondary ventilator to pull microdust from secondary filters and pass it to cyclone seperator and dust compactor with fresh air exit to secondary filters.

- Cyclone separator and dust compactor to separate microdust taken from secondary filter and allow to fresh air back to secondary filter.

- Better performance due to minimised pressure loss.

- Compact design and hence less space required.

- Waste is compacted and hence easy to handle.

- Optimum utilisation of fans ensures complete cleanliness.

- Cost effective.

- Can be incorporated in existing set ups.

- Easy to maintain, low maintenance costs.

- Sturdy gearbox design and high quality rotating parts and nozzles for longer life.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Mild Steel |

| Shape | Different shape available |

| Country of Origin | India |

| Application | Industrial |

Manifold blocks used for space saving connections of number of directional control valves to common delivery and return line are the basic components of any hydraulic systems / power packs. Bajaj manufactures manifold blocks from