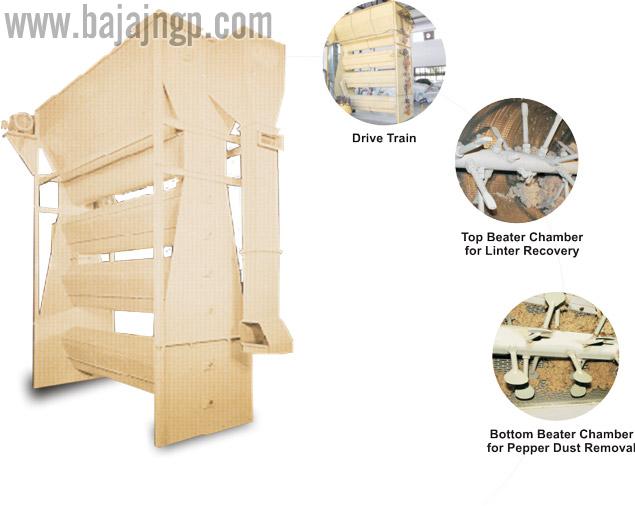

IMPCO-Delinting

Leading Manufacturers, Exporters, Wholesaler, Retailer of 4620 Bajaj CEC Hull Beater, Bajaj CEC Decorticator, Bajaj CEC Seed Cleaner, Bajaj-CEC LE 176 Delinter and LC410D Bajaj CEC Linter Cleaner Machine from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Power Source | Electric |

| Type | Hulling Machines |

| Country of Origin | India |

| Brand | Bajaj |

| Top Chamber | 5 PH , 1500 RPM |

| Bottom Chamber | 2 HP, 1500 RPM |

| Air Requirements | 750 CFM |

Unsurpassed in efficiency, the model 4620 Hull Beater is uniquely designed with a built in tailing beater eliminating the need for additional conveying systems. Capable of handling capacities in excess of 200 tons per day of delinted & undelinted cottonseed, the model 4620 is unequaled in the industry. When combined with the CEC/BAJAJ decorticator /separator system, oil in hulls is maintained at a low level by residual meat recovery to maximum extent, even with 12 % to 14% lint on hulls.

ENERGY SAVING FEATURES- Built in tailing beater eliminating the need for additional conveying systems

- Common mechanical conveying system for Hull discharge from both chambers.

- Capable of handling in excess of 200 tons per day of delinted and un delinted seed.

- Electric motors are conveniently located for ventilation & easy maintenance

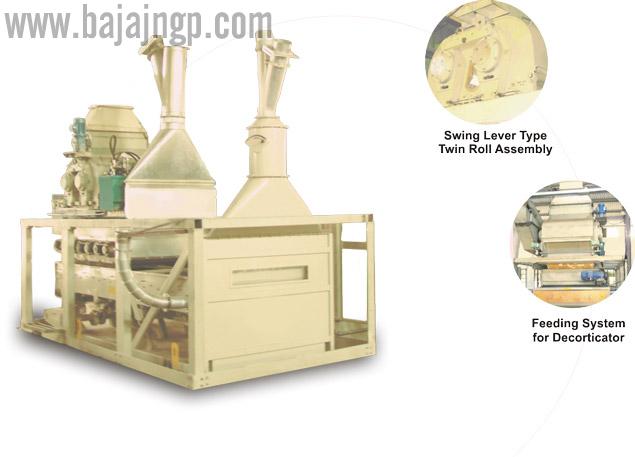

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Capacity – Black Seed | 8 to 9 TPH |

| Twin Roll Motor | 25 HP 1500 RPM |

| Hydraulic Unit Motor | 2 HP 1200 RPM |

| Feeder Motor | 1 HP Variable |

| Cutting Segments | 38 (19 per roll) |

| Shaker Tray Motor | 3 HP |

| Basket Beater Motor | 1.5 HP |

| Air Requirement | 5200 CFM |

CEC was the first to envision and implement the modern twin-roll hulling design since 1962. First to incorporate a decorticator with a basket beater and high speed separation. First to successfully process undelinted cottonseed with lowest kernel with hull. Highest Capacity per meter width of twin roll drum.

SALIENT FEATURES- l No uncut seed recycling – virtually 100% of seed is cut and processed

MECHANICAL ADVANTAGES

- Replaceable cutting surface on decorticator roll will process the highest tonnage at the lowest cost.

- Two removable Basket Beater Trays provided for ease of processing multiple oil seeds such as cottonseed delinted / undelinted, sunflower, soybean and groundnut etc.

- Three hull aspiration ducts allows for maximized hull removal and meat purification to obtain desired protein levels.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Brand Name | Bajaj |

| Type | Seed Cleaning Machine |

| Country of Origin | India |

| Fan Motor | 10 HP |

| Motor for Sieve Boat | 3 HP |

| Screen Size L*W | 800 * 1500mm |

- Quick assembly of attachments

- Designed for higher safety

- User friendly

- Handling big loads

We offer custom designed attachments for material handling by tractors in cotton ginning and pressing plants. Bajaj employs latest design techniques and manufacturing techniques to provide rigid, high quality attachments for

- Cotton Bale Handling

- Loose cotton handling

- Seed Heaping and loading to bagging hoppers

- Heaping of cotton

FEATURES & BENEFITS

- Heavy duty applications

- Anti friction bushes and high quality hardened pins at all points

- Robust construction for long life

- High quality hydraulic systems for better performance

- Level indicators available wherever necessary

- Bucket sizes as per customer’s requirements

- Easily detachable units

- Lifting heights upto 17 ft.

- Non metallic coverings for tips to avoid chances of spark or fire

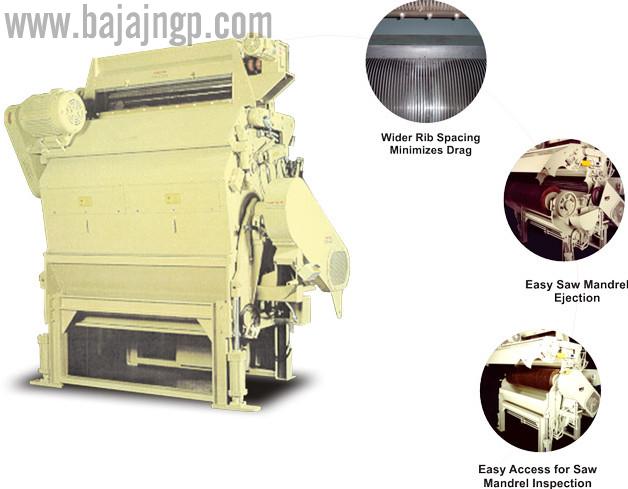

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Saw Motor | 30 HP 1500 RPM |

| Float Motor | 20 HP 1500 RPM |

| Brush Motor | 3HP 1000 RPM |

| Feeder Motor | 1HP with VFD |

| Saw Blanks | 176 Nos |

| Doffing Brush | 40 Rows x 2 |

| Air Requirement | 2200 CFM |

| Capacity-Mill Run | 35 TPD per M/C |

| Linter Recovery | 4 to 5% on Mill Run |

| Seed Moisture | 5 to 10% |

BAJAJ-CEC LE 176 DELINTER is designed for High Capacity cotton Seed delinting at rates upto 4.2 tons per hour. It is designed for maximum efficiency and production of superior quality Linter at industry leading production rates. Maximum efficiency is obtained through precise engineering in a user friendly design to facilitate operation and maintenance. It has 176 Saw Blanks made of superior & special steel material.

ENERGY SAVING FEATURES- Efficient Roll Box design minimizes drag for an easier flow of seed Mass.

- Lowest Energy – to capacity ratio in the Industry.

- Saw Mandrel made of mechanical tubing provides smooth operation

- Electric motors are conveniently located for ventilation & easy maintenance

- Positive tooth belt drives eliminate slippage & provides efficient power transmission

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Power Source | Electrical |

| Feature | Optimum Finish |

| Type | Lint Cleaner |

| Function | Dust Lint Cleaning |

| Country of Origin | India |

| Brand | Bajaj |

BAJAJ-CEC LC 410D is uniquely designed with the paddle sections capable of handling capacities in access of 10 tons per day of recovered linter. The cellulose yield of removed linter is maintained at maximum. The linter cleaner accommodates automatic screen cleaning at desired intervals. The LC-410D provides additional cleaning where its needed the most, three times the effective pepper section cleaning than the competitors.

SALIENT FEATURES

- Linter Cleaner also incorporates Automatic Screen Cleaning which blows down the entire length of both hull pepper sections with high-pressure air. Manual blow-down and unnecessary shutdown are thus eliminated.

- The blow down system is PLC controlled and can be programmed both for duration & frequency of the air blasts.'

- 28% greater cleaning surface area for first-pass cleaning than others.

- Electric motors are conveniently located for ventilation & easy maintenance.

- Reclaim section designed to accommodate any additional shale removal which may be required.