Ginning & Pressing Machinery

Leading Manufacturers, Exporters, Wholesaler, Retailer of Air Separator, Air Separator with Vaccum Wheel, Auto Feeder for Ginning Machine, Belt Conveyor, Bucket Elevator, Cotton Bale Wire Ties, Cotton Baling Press, Cotton Boll Opener, Cotton Dispensing System, Cotton Lint Cleaner Machine, Cotton Pre Cleaner, Fire Detector, Fully Automatic Ginning Plant, Horizontal Pre Cleaner, Magnum Double Roller Ginning Machine, Overflow Hopper, Platina Double Roller Ginning Machine, Pneumatic Conveying Systems, Raw Cotton Horizontal Pre Cleaner, Rotary Air Lock with Dust Receiver, Seed Cotton Conveying System and Seed Cotton Distribution Screw Conveyor from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Mild Steel |

| Specialities | Excellent Functionality, Less Maintenance, Easy To Use |

| Country of Origin | India |

Salient Features :

- Efficient and Gentle separation of material (Seed Cotton & Lint) from air.

- Optimizes ginning per formance.

- Robust construction; longer life.

- Made with superior technical know how.

- Available in different models with different feeding systems for specific requirements.

- Removes dust, fine trash & short fibres to good extent.

- Max suction area for extracting air from material and efficient material discharge at the bottom.

- Robust Body

- Simple Operations

- Easy Maintenance

- Interchangeability of Spares

- Less Power Consumption

- Higher Output

- Higher Profits

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Usage | Industrial |

| Specialities | Excellent Functionality, Less Maintenance, Ruggedly Constructed |

| Country of Origin | India |

| Brand Name | Bajaj |

- Separate material efficiently.

- Robust construction for longer life.

- Made with superior technical know how.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Removes dust, fine trash & short fibres.

- Max opening for efficient material discharge.

- Optimizes conveying performance

- Made with superior technical know how

- Robust Construction

- Protects material quality

- Efficient screen cleaning by well designed Wiper

- Efficient discharge through well designed Vaccum Wheel

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj Steel |

| Country of Origin | India |

| Model | Auto Feeder For Ginning Machine |

| Power Consumption | Electric |

| Speed | 35-40 RPM |

FEATURES & BENEFITS

- No Extra Electricity.

- Saves man power/ Considerable saving in labour cost.

- Proper feeding of Raw Cotton to Gin Machine.

- Easy to maintain; Low maintenance cost.

- No need to disassemble the Auto Feeder for machine maintenance.

- No need to disassemble the Auto Feeder for changing Auto Feeder cloth.

- No need to disassemble the Auto Feeder for changing Auto Feeder cloth.

- Increases productivity between 15% to 20%.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Metal |

| Size | Standard |

| Feature | Excellent Quality, Scratch Proof, Vibration Free |

| Type | Converyors |

| Country of Origin | India |

Feature

- Robust construction

- Maintenance Free

- Simple Operations

- Reduces manpower

Bajaj heavy duty Belt Conveyors are designed to transport bulk materials over both short and long distances. These are ideal for conveying a wide variety of bulk materials from sluggish to free flowing and small to large lump sizes.

Bajaj Belt Conveyors are custom designed and can convey material both horizontally and at an inclination and are available in various sizes and specifications depending upon the application, efficiency of the system, material density to be carried etc.

SALIENT FEATURES

- Considerable saving in labour cost.

- Available in different model for specific requirements like jobs for sorting, inspection, assembling, transportation of bulk materials.

- Easy installation facilitated due to quick connection between components.

- Easily operated adjustment devices.

- Precisely machined rollers to facilitate belt movement

- Effective skirting design for any inclination which facilitates many point dropping material on the belt conveyor.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Driven Type | Electric |

| Application | Industrial |

| Country of Origin | India |

| Dimension(L*W*H) | Customized |

| Quality | Optimum |

Bajaj Bucket Elevators are ideally suited to elevate bulk materials from sluggish to free flowing vertically. These bucket elevators are manufactured for capacities up to 15000 Kg/hr. depending upon the material requirements.

Bajaj Bucket Elevators consists of rectangular rigid mild steel housing with a tangential inlet in the bottom section and an inclined outlet in the top section. Bajaj Bucket Elevators are of centrifugal type with rigid seamless mild steel buckets mounted on open ended belts. These are anti static oil repellent in nature. The drive unit comprises of an electrical motor coupled to reduction gear box mounted on the maintenance platforms attached to the top section.

- Robust construction

- Completely enclosed for dust free operation

- Low maintenance

- Made with superior technical know how

- Simple Operations

BENEFITS

- Considerable saving in labour cost.

- Available in different models for specific requirements like bagging, transferring to conveyors etc.

- Bucket design ensures maximum fill in buckets and prevent discharge interface with proceeding buckets while in operation.

- Effective inspection windows on intermediate sections.

- Easy installation facilitated due to quick connection between components.

- Precise machined head and tail pulleys to facilitate belt movement.

- Easily operated adjustment devices.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Brand |

| Type | Cotton Bales |

| Country of Origin | India |

| Wire Gauge | 0.6mm-4mm |

| Surface Treatment | Galvanized |

| Application | Wire Mesh, Cable Armouring |

| Size | Custom |

- High quality galvanized wire

- Easy to feed , bend and tie

- Designed effectively for break load, tensile and elongations and hence highly reliable

- Available for all bale densities

- Double loop for strong locking

- High Strength

- High Reliability

- Suitable for High/Universal Density Bales

- Made from special steel

- Rust proof

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Automatic Grade | Automatic |

| Country of Origin | India |

| Tramper | Hydraulic |

| Application | Industrial |

International Cotton Baling Press, To Revolutionise Cotton Baling

Feature

- Medium Capacity (15-18 Bales/hr) & (20 -22 / 25 Bales/hr)

- High capacity (30-35 Bales/hr)

- Fully automatic

- High/Universal Density Bales

- Lowest cost per Bale

- Most Profitable

We excel in manufacturing wide range of automatic and semi-automatic Baling Presses for cotton, textile, HDPE bags, coir, bio mass and many other applications. However we are the world leader in Cotton Baling Presses.

- Fully Automatic

- Double Box Press

- High speed automatic revolving of boxes

- High/universal Density Bales

- Most Profitable

- International Specifications

- Highest Work Safety

- Lowest Cost Per Bal

- Lowest Power Consumption Per Bale

- Lowest maintenance

- Lowest packing material cost

- Lowest manpower requirements

- Very heavy duty structure for longer life

- High pressure power pack

- Door less mechanism

- Down packing, no underground pit

- 8 bales / hour

- Semi Automatic

- Single box press

- High/ Universal Density Bales

- Most Profitable

- International Specifications

- Highest Work Safety

- Lowest Cost Per Bale

- Lowest Power Consumption Per Bale

- Lowest maintenance

- Lowest packing material cost

- Lowest manpower requirements

- Very heavy duty structure for longer life

- High pressure power pack of German Technology

- Door mechanism

- Down packing, no underground pit

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Length | 12’ |

| Cleaning Capacity / Hour(avg) | 600 Kgs Raw Cotton |

| Connected Total Power | 5 HP |

| Height from Top of Hopper | 5 1/4’ |

| Height from Top of Cover | 4 1/4’ |

| Weight (approx) | 750 Kgs |

Features & Benefits :

- Movable

- Easy to operate

- Fully automatic

- Robust construction

- Maximizes profits

An additional profit machine :

- Designed to open raw cotton bolls by air turbulence and clean lower grades of cotton by separating dust, leaves immature bolls etc.

- Most efficient for cleaning zoda, leafy and other lower grades of raw cotton as well as collection from pre-cleaners.

- Reduces manpower required for sorting, by allowing dust, leaves and immature bolls to fall below through grids with holes of different sizes for separate collection.

- Opened and cleaned raw cotton delivered at the discharge-end

- Recovers useful raw cotton from trash cotton collections.

- No damage to cotton fibre in the process.

Robust Construction :

- A large capacity fan is provided before inlet to create sufficient air pressure to aerate raw cotton by air turbulence.

- Large diameter beaters are provided to separate dust, leaves and immature bolls etc. and push the clean raw cotton towards the discharge-end.

- The grids are made of heavy- gauge steel sheets.

- The round holes of different- size grids do not get clogged easily.

- The top cover of the machine is of painted cr sheets to make the machine weather- resistant.

- The main shaft runs on three heavy-duty ball bearing encased in dust- proof housing to give trouble free service for number of years, with lower power consumption.

Safe and Trouble free :

- Guarding at the feed-end as well as at the discharge-end has been provided for safety purpose.

- Totally enclosed by sheet metal with door to collect trash & pre-matured bolls separately.

- Suitable base for fitting electric motor has been provided to eliminate slide rails.

- The covers of the machine are tightened by fly-nuts to enable the operator to attend the machine without using spanner.

- Driving arrangement is totally enclosed.

Optional Accessories

- Wheel arrangement

- Elelctric motor

- Transmission pulley & belt

- Starter

- Switch

- Heavy-duty,four core flexible cable

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Application | Cotton Ginning,Cotton Mill |

| Country of Origin | India |

| Power Source | Electric |

| Phase | Single |

We Bajaj Steel Industries Limited, Nagpur take this opportunity to introduce ourselves as a company that has achieved global proportions in Cotton Ginning and Pressing technology.

FEATURES- Consistent and Uniform Opening And Feeding

- Higher Productivity

- Reduced Manpower cost

- Improves the quality of Lint

- Lesser trash content in raw cotton

- Lesser Contamination of Seed Cotton

- Robust Construction

- Uniform and adequate feeding at all points

- Optimizes Ginning performance

- Ease of use

- Reduced Manpower Costs

- Made with superior technical know how

- Easily Accommodated in existing systems

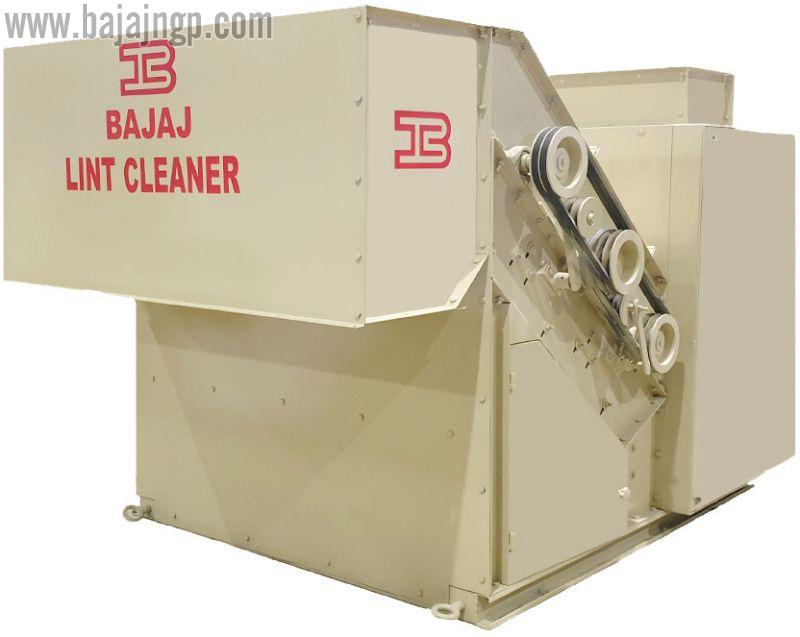

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Brand Name | Bajaj |

| Application | Lint Cleaning |

| No. of cleaning cylinders | Six |

| Width | 1200 /1500 / 1800 mm |

Features & Benefits :

- Removes seeds coats, leafy matter after ginning.

- Improves lint grade & appearance.

- Reduces trash content & other contamination.

- Eliminates micro-dust effectively.

- Precise design preserves fiber properties.

- Removes short fiber clusters from ginned lint.

- Better quality lint yields higher returns.

- Easy to maintain; Low maintenance cost.

- Available in different models with different feeding systems for specific requirements.

- Can be incorporated in pneumatic conveying system for online cleaning.

- Considerable saving in labour cost.

- Protects fiber quality

- Cleans gently and efficiently

- Reduces trash content

- Removes seed coats, leafy matter, short fibres, microdust etc. from ginned lint.

- Improves lint grade & appearance.

- Made with superior technical know-how.

- Robust construction; longer life.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Power | 4-7.5 HP |

| Country of Origin | India |

| Brand | Bajaj |

| Model Name/Number | Cotton Pre Cleaner |

| I Deal In | New Only |

| No. of Cleaning Cylinders | 4 |

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction ; longer life

- Protects gin from damage by impurities

- Made with superior technical know-how

- Reduces maintenance of ginning machines

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction; longer life

- Protects gin from damage by impurities

- Made with superior technical know-how

- Reduces maintenance of ginning machines.

- Removes yellow/ pre-matured bolls, trash, stones and others impurities from raw cotton, there by improving the quality of raw cotton prior to ginning.

- Increases productivity of ginning machines

- Reduces load on ginning machines

- Auto feeding made easy and trouble-free

- Auto feeder maintenance reduced to minimum

- Better quality of lint yields higher returns

- Considerable saving in labor cost

- Available in different models with different feeding systems for specific requirements.

- All models can also be wheel-mounted for easy mobility.

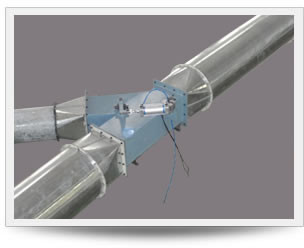

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Country of Origin | India |

| Spark Detection | Less than 8 Mili Seconds |

| Relay Response | Less Than 10 mili seconds |

| Output signal to Relay | 24 mili seconds |

| Detect Sparks at Speeds | Upto 50 m / sec |

| Operating Temperature | -40 to 60 Degree C |

Fire Detector on a Pneumatic Line

Fire Detection Systems are primarily used for fire prevention in pneumatic conveying systems by detecting the spark and diverting the material to extinguisher chambers / areas.

These fire detector / divertors detect smoke and heat very quickly and thus curtail the chances of any fire. This system detects sparks of any nature which are fire generating. Fitted with high efficient sensors to detect the spark or smoke and triggers flow diversion gates or divertors so that the fire never goes into the main line and is diverted to extinguisher chambers / areas.

- Dependable operation

- Minimizes losses

- German technology

- Easy cleaning arrangement for sensors

SALIENT FEATURES

- Minimizes losses which may be caused by fire.

- Spark detection, burning or flame detection response time is very quick.

- User friendly

- Can be easily accommodated into existing production lines with very small or no changes.

- Downtime of all facilities is reduced to minimum.

- Sensors are very easy to clean and hence specialized manpower not needed to run this system.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Automation | Fully Automatic |

| Country of Origin | India |

| Application | Automatic Cotton Ginning Plant |

| Material | Mild Steel |

Bajaj manufactures complete automation solutions for ginning plants. Our automation systems are most advanced in the industry where in we provide Pre Cleaners, Post Cleaners, Conveying Systems, Automatic Feeding Systems, Over Flow Handling, Feed Regulators and PLC’s to synchronize and control many of the processes.

- Feed Regulation of Seed Cotton to Gins – Auto Regulators are provided to regulate the flow of seed cotton from screw feeder to Gins. Auto regulators are fitted below the distribution conveyor for centralized unifrom feeding to each Gin in controlled manner.

- Storage & Distribution – Surging of Seed Cotton to maintain flow of the same in the system for uniform and adequate feeding. Surge hoppers are VFD driven with sensors to maintain the level of Seed Cotton.

Our Product Line include:

Double Roller Cotton Gins ~ Auto Feeder ~ Baling Presses ~Pre-Cleaner ~Lint Cleaner~Seed Cotton Opener & Cleaner~Pneumatic Conveying and Distribution System of Unginned Cotton for Automatic Plants~Belt conveyors ~ Pneumatic Conveying System for Cotton lint~Cotton Seed Conveyors, Elevators~Electricals & Spares etc.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Color | Tan |

| Country of Origin | India |

| Brand | Bajaj |

| No. of Cleaning Cylinders | Eight |

| Width | 1200/1500/1800 mm |

| Raw cotton cleaning capacity per hour | 3000/6000/9000 Kgs. |

| Connected total power | 7 H.P. / 7 H.P./ 9.5 H.P. |

| Operating Speed (at different Rollers) | 185 – 300 rpm |

| Wheel-mounting (optional) | Yes |

| Feeding system | Mechanical / Pneumatic / Manual |

FEATURES & BENEFITS

- Removes immature bolls efficiently

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction ; longer life

- Protects gin from damage by impurities

- Made with superior technical know-how.

- Reduces maintenance of ginning machines

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction; longer life

- Protects gin from damage by impurities

- Made with superior technical know-how

- Reduces maintenance of ginning machines.

- Removes yellow/ pre-matured bolls, trash, stones and others impurities from raw cotton, there by improving the quality of raw cotton prior to ginning.

- Increases productivity of ginning machines

- Reduces load on ginning machines

- Auto feeding made easy and trouble-free

- Auto feeder maintenance reduced to minimum

- Better quality of lint yields higher returns

- Considerable saving in labour cost

- Available in different models with different feeding systems for specific requirements.

- All models can also be wheel-mounted for easy mobility.

- Trash removal can be mechanical/ manual/ pneumatic.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Country of Origin | India |

| Brand | Bajaj Steel |

| Model | Machine |

| Rotation of Machine Pulley | Clockwise |

| Seed Discharge | Slides / Vertical |

| Gear | Helical |

Bajaj Double Roller Cotton Gin Highest out Turn of Lint than other Ginning System. cleaner Seeds with minimum Cotton Linter on it.

We have been awarded the “Largest and modern cotton ginning & pressing machinery manufacturer in India” by the hands of then Hon’ble Union minister of textile Govt. of India Mr. Shankersinh Vaghela.

Bajaj DR gins give highest out turn of lint with better seed quality at lowest maintenance and per unit cost of production. Similarly high efficiency Bajaj down packing cotton baling press produces highest number of bales at lowest cost per bale. We offer complete cotton ginning, pressing, cleaning, conveying and handling solutions and turn key ginning and pressing plant machinery.

- Increased leather roll diameter

- 14 sealed / Pre greased bearings

- Only 3 greasing points

- Improved beater housing for easy setting

- Adequate weights on leather roll for higher production

- Maximum strength to Gin upto 50 G/Tex cottons

- Use of superior material for highest strength of spare parts Highest out Turn of Lint than other Ginning System. cleaner Seeds with minimum Cotton Linter on

- About 50% lower vibration

- Magnum Machine design is compatible for use of normal greasing bearing as all 2RS bearing area has provision for fitment & use of normal greasing bearing (in emergency case)

- Highest production in same size DR Machines

- Less Power Consumption per unit of production

- One to one replacement on Golden Jubilee/ Ultra models

- Less man power as less greasing points

- Longer wear life of leather roller

- Interchangeability of spares

Over 100,000 Bajaj Double Roller Ginning Machines are operating throughout India and various other countries like Bangladesh, Egypt, Indonesia, Kenya, Madagascar, Myanmar, Nepal, Nigeria, Peru, Shri Lanka, Tanzania, Uganda, Zambia, Zimbabwe etc.

BENEFITS

- Protects Fibre Quality ; Gives Production of Clean ; Lustrous Cotton Lint.

- Works efficiently ; reduces cost and Adds to profitability.

- Engineering experiences and expertise combined to ensure lowest operational and maintenance cost.

- Consumes less power.

- All gears, connecting rod, head, beater arm, swing lever etc. are made of high Nodularity ductile iron.

- All rotating parts are provided with precision bearings to reduce friction for optimum efficiency.

- Connecting housing is provided with heavy duty self aligning roller bearing.

- Leather roller shafts are interchangeable and if one side of the roller is worn out, It can be reversed.

- Lint output remains uniform on full length of the rollers.

- Moving parts are housed in dust proof gear box for smooth running.

- Lubrication is pressure fed, dust proof greasing system.

- Special hardened bushes for weight levers and swing levers to ensure smooth working of gin.

- Over 100,000 gins are in efficient operation in India & Abroad.

- Fully backed by after sales services, provided by team of trained and Competent engineers.

- High quality replacement parts and spares available at all times.

- Lowest power consumption per quintal lint ginned

- Fully machined dynamically balanced fly wheel / machine pulley.

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish & Tolerances to provide enhanced life of the machine & zero down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

- Box Spanner, M12 & M16, T Spanner M10, 1/8” BSP Threaded T Spanner, Beater Adjustment Gauge.

- Foundation Templates, Foundation Bolts, Motor Rails, Motor Pulley, Guard For Pulley, V Belts, Seed Screw Conveyor, Roll Press, Roll Cutting Stand, Cotton Bag, Weighing Stand, Lint Filling Platform, Bus Bar Panel With All Required Fittings, Platform Structure, Complete Range Of Spares, Doffer Roller Assembly, Automatic Roll Grooving Machine, Electrical Motor & Electricals.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Metal |

| Power Source | Electric |

| Country of Origin | India |

| Connected total power | 2 HP |

| Capacity (Kgs /Hr) of Seed Cotton | 1500Kg |

- Substantial savings in labour cost

- Robust Construction

- Made with superior technical know how

- Easily accomodated in existing setups

- Robust construction; longer life.

- Form an integral part of Seed Cotton distribution system to Gins.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Programmed to handle and recycle the unused Seed Cotton of Screw Conveyor Feeder for Seed Cotton.

- Variable Feed Rates for specific requirements.

- Supplied with high quality electrical accesories and dust proof sensors for efficient performance.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Brand | Bajaj Steel |

| Model | Platina |

| Seed Discharge | Slides / Vertical |

| Rotation of Machine Pulley | Clock Wise |

| Gear | Helical |

Bajaj Double Roller Cotton Gin

Highest strength Cotton Ginning machine having highest output per hour for same size DR

We have been awarded the “Largest and modern cotton ginning & pressing machinery manufacturer in India” by the hands of then Hon’ble Union minister of textile Govt. of India Mr. Shankersinh Vaghela.

Bajaj DR gins give highest out turn of lint with better seed quality at lowest maintenance and per unit cost of production. Similarly high efficiency Bajaj down packing cotton baling press produces highest number of bales at lowest cost per bale. We offer complete cotton ginning, pressing, cleaning, conveying and handling solutions and turn key ginning and pressing plant machinery.

Why PLATINA DR ?

- Increased leather roll diameter

- 14 sealed / Pre greased bearings

- Only 3 greasing points

- Improved beater housing for easy setting

- Adequate weights on leather roll for higher production

- Maximum strength to Gin upto 50 G/Tex cottons

- Use of superior material for highest strength of spare parts

- About 50% lower vibration

- Platina Machine design is compatible for use of normal greasing bearing as all 2RS bearing area has provision for fitment & use of normal greasing bearing (in emergency case)

- Highest production in same size DR Machines

- Less Power Consumption per unit of production

- One to one replacement on Jumbo/ Super models

- Less man power as less greasing points

- Longer wear life of leather roller

- Interchangeability of spares

Over 55000 Bajaj Double Roller Ginning Machines are operating throughout India and various other countries like Bangladesh, Egypt, Indonesia, Kenya, Madagascar, Myanmar, Nepal, Nigeria, Peru, Shri Lanka, Tanzania, Uganda, Zambia, Zimbabwe etc.

BENEFITS

- Protects Fibre Quality ; Gives Production of Clean ; Lustrous Cotton Lint.

- Works efficiently ; reduces cost and Adds to profitability.

- Engineering experiences and expertise combined to ensure lowest operational and maintenance cost.

- Consumes less power.

- All gears, connecting rod, head, beater arm, swing lever etc. are made of high Nodularity ductile iron.

- All rotating parts are provided with precision bearings to reduce friction for optimum efficiency.

- Connecting housing is provided with heavy duty self aligning roller bearing.

- Leather roller shafts are interchangeable and if one side of the roller is worn out, It can be reversed.

- Lint output remains uniform on full length of the rollers.

- Moving parts are housed in dust proof gear box for smooth running.

- Lubrication is pressure fed, dust proof greasing system.

- Special hardened bushes for weight levers and swing levers to ensure smooth working of gin.

- Over 100,000 gins are in efficient operation in India & Abroad.

- Fully backed by after sales services, provided by team of trained and Competent engineers.

- High quality replacement parts and spares available at all times.

- Lowest power consumption per quintal lint ginned

- Fully machined dynamically balanced fly wheel / machine pulley.

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish & Tolerances to provide enhanced life of the machine & zero down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

FREE ACCESSORIES

- Box Spanner, M12 & M16, T Spanner M10, 1/8” BSP Threaded T Spanner, Beater Adjustment Gauge.

OPTIONAL SUPPLY

- Foundation Templates, Foundation Bolts, Motor Rails, Motor Pulley, Guard For Pulley, V Belts, Seed Screw Conveyor, Roll Press, Roll Cutting Stand, Cotton Bag, Weighing Stand, Lint Filling Platform, Bus Bar Panel With All Required Fittings, Platform Structure, Complete Range Of Spares, Doffer Roller Assembly, Automatic Roll Grooving Machine, Electrical Motor & Electricals.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Driven Type | Penaumatic |

| Automatic Grade | Automatic |

| Application | Industrial Use |

| Country of Origin | India |

| Design | Customized |

Galvanised Pipes: We provide galvanised pipes from 5” dia to 36” dia for various applications these are made in length upto 6 mtr connected to each other by Flanges at the ends with suitable filler material to give leak proof joints.

Elbows or bends for vertical movement of material.

G.I./M.S. divertors are usually provided to fascilitate multi point material lifting.

Centrifugal fans are used to create pressure differentials to induce efficient airflow to carry the material.

Stone Catcher / Rock Taps: Stone catchers are the devices to separate rocks, green bolls and any other heavy objects in the cotton seed.

These stone catchers are usually made of mild steel connected to the raw cotton conveying line before it enters the gin house or before seed enters into seed cleaner. Bajaj stone catchers have been designed and manufactured so as to fascilitate rocks and other heavy objects efficiently without considerable pressure losses.

Stone catchers are combination of a mild steel chamber for setting heavy objects which has a counter weight trap door and on accumulating pipe wherein the heavy objects gets unloaded whereas centrifugal force generated fans is used to convey material. The trap door is held closed by suction while the material gets conveyed. The rocks etc can be dumpped by opening the trap door.

Pneumatic conveying systems use air as the transport medium. Pneumatic conveying is facilitated by combination of following products:

- Galvanised Pipes: We provide galvanised pipes from 5” dia to 36” dia for various applications these are made in length upto 6 mtr connected to each other by Flanges at the ends with suitable filler material to give leak proof joints.

- Considerable saving in labour cost.

- Available in different model for specific requirements like jobs for sorting, inspection, assembling, transportation of bulk materials.

- Easy installation facilitated due to quick connection between components.

- Easily operated adjustment devices.

- Precisely machined rollers to facilitate belt movement

- Effective skirting design for any inclination which facilitates many point dropping material on the belt conveyor.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| No. of Cleaning Cylinders | Eight |

| Width | 1200/1500/1800 mm |

| Raw Cotton Cleaning Capacity per Hour | 3000/6000/9000 Kgs. |

| Connected Total Power | 7 H.P. / 7 H.P./ 9.5 H.P. |

| Operating Speed (at different Rollers) | 185 – 300 rpm |

| Wheel-mounting (optional) | Yes |

| Feeding System | Mechanical/ Pneumatic/ Manual |

Features & Benefits :

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction; longer life

- Made with superior technical know-how

- Reduces maintenance of ginning machines.

- Removes yellow/ pre-matured bolls, trash, stones and others impurities from raw cotton, there by improving the quality of raw cotton prior to ginning.

- Increases productivity of ginning machines

- Reduces load on ginning machines

- Auto feeding made easy and trouble-free

- Auto feeder maintenance reduced to minimum

- Better quality of lint yields higher returns

- Considerable saving in labour cost

- Available in different models with different feeding systems for specific requirements.

- All models can also be wheel-mounted for easy mobility.

- Trash removal can be mechanical/ manual/ pneumatic.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Application | Mechanical Industry |

| Type | Rotary Air Lock |

| Country of Origin | India |

- Discharges material efficiently with air back pressure.

- Heavy Duty construction; longer life.

- Made with superior technical know how.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Max opening for efficient material discharge.

- Robust Construction

- Made with superior technical know how

- Less space required

- Low Maintenance

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Material | Mild Steel |

| Color | Green |

| Performance | Optimum |

| Specialities | Easy to Operate |

Seed Cotton Conveying systems are broadly classified as follows:

- Mechanical Conveying System

- Pneumatic Conveying System

The typical mechanical conveyors used in a ginning plants includes

- Screw type distribution conveyor feeders for seed cotton

- Belt conveyors of various types

Screw type distribution conveyor feeders for seed cotton

- Available in various sizes upto 450 mm diameter

- Efficient distribution of seed cotton to each Gin to get optimum production

- Efficeint overflow handling

- Effective alignment for maximum length

Belt Conveyors

- Available in various sizes

- Smooth carrying of seed cotton from cotton storage to pre-cleaner or hot box or suction system etc.

- Distribution of seed cotton to gins

- For picking of foreign material / contaminents before feeding to pre-cleaner or Gin.

- Robust construction for longer life and trouble free operation

PNEUMATIC CONVEYING SYSTEM

Bajaj manufactures most efficient pneumatic conveying systems for cotton seed. Pneumatic conveying offers an ideal choice for transportation of seed cotton, lint, cotton seed and other materials as the material is transported in a closed pipeline which protects it from environmental contaminations and also are smooth, trouble free, time saving and cheaper for long distance transportations.

- Available in spiral and plain construction

- Higher thickness of sheets for longer life

- Heavy duty bends, diverters, expander and reducers etc.

- Well designed joining

- Efficient removal of foreign particles

Galvanised Pipes: We provide galvanised pipes from 5” dia to 36” dia for various applications these are made in length upto 6 mtr connected to each other by Flanges at the ends with suitable filler material to give leak proof joints.

Cyclones:- Bajaj cyclones designed and manufactured to seed discharge rate from Roots Blower. These cyclones are made of mild steel and are used for seed feeding to the rotary air lock above the seed bagging conveyor.

Some of the sailent features of Cyclones are as below :

• Robust Construction

• No maintenance

• Long life

crew Conveyor for Seed Bagging :-

- Available in various sizes upto 450 mm diameter

- Efficient distribution of seed for multi point bagging

- Effective alignment for maximum length

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Shape | Rectangular |

| Usage | Moving Goods |

| Specialities | Long Life, Excellent Quality, Corrosion Proof |

| Country of Origin | India |

| Brand Name | Bajaj |

| Surface | Galvanized |

| Structure | Conveyor System |

- Available in various sizes upto 450 mm diameter

- Helicoids of high quality carbon steel provides smooth surface with no sharp edges.

- All rotating parts are provided with precision bearing to reduce friction for optimum efficiency.

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish and tolerances to enhance life of the machine & minimizes the down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

- Bearings are enclosed in bracket housing with dust proof covers thus enhancing the life.

- Troughs designed for optimum feeding and carrying of material to machine or for bagging.

- Reduces man power in the process largely.

- Robust Construction

- Long life

- Maintenance free

- Uniform and adequate feeding at all points

- Ease of use

- Protects fibre quality

- Made with superior technical know how