| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Country of Origin | India |

| Brand | Bajaj Steel |

| Model | Machine |

| Click to view more | |

Product Details

Bajaj Double Roller Cotton Gin Highest out Turn of Lint than other Ginning System. cleaner Seeds with minimum Cotton Linter on it.

We have been awarded the “Largest and modern cotton ginning & pressing machinery manufacturer in India” by the hands of then Hon’ble Union minister of textile Govt. of India Mr. Shankersinh Vaghela.

Bajaj DR gins give highest out turn of lint with better seed quality at lowest maintenance and per unit cost of production. Similarly high efficiency Bajaj down packing cotton baling press produces highest number of bales at lowest cost per bale. We offer complete cotton ginning, pressing, cleaning, conveying and handling solutions and turn key ginning and pressing plant machinery.

- Increased leather roll diameter

- 14 sealed / Pre greased bearings

- Only 3 greasing points

- Improved beater housing for easy setting

- Adequate weights on leather roll for higher production

- Maximum strength to Gin upto 50 G/Tex cottons

- Use of superior material for highest strength of spare parts Highest out Turn of Lint than other Ginning System. cleaner Seeds with minimum Cotton Linter on

- About 50% lower vibration

- Magnum Machine design is compatible for use of normal greasing bearing as all 2RS bearing area has provision for fitment & use of normal greasing bearing (in emergency case)

- Highest production in same size DR Machines

- Less Power Consumption per unit of production

- One to one replacement on Golden Jubilee/ Ultra models

- Less man power as less greasing points

- Longer wear life of leather roller

- Interchangeability of spares

Over 100,000 Bajaj Double Roller Ginning Machines are operating throughout India and various other countries like Bangladesh, Egypt, Indonesia, Kenya, Madagascar, Myanmar, Nepal, Nigeria, Peru, Shri Lanka, Tanzania, Uganda, Zambia, Zimbabwe etc.

BENEFITS

- Protects Fibre Quality ; Gives Production of Clean ; Lustrous Cotton Lint.

- Works efficiently ; reduces cost and Adds to profitability.

- Engineering experiences and expertise combined to ensure lowest operational and maintenance cost.

- Consumes less power.

- All gears, connecting rod, head, beater arm, swing lever etc. are made of high Nodularity ductile iron.

- All rotating parts are provided with precision bearings to reduce friction for optimum efficiency.

- Connecting housing is provided with heavy duty self aligning roller bearing.

- Leather roller shafts are interchangeable and if one side of the roller is worn out, It can be reversed.

- Lint output remains uniform on full length of the rollers.

- Moving parts are housed in dust proof gear box for smooth running.

- Lubrication is pressure fed, dust proof greasing system.

- Special hardened bushes for weight levers and swing levers to ensure smooth working of gin.

- Over 100,000 gins are in efficient operation in India & Abroad.

- Fully backed by after sales services, provided by team of trained and Competent engineers.

- High quality replacement parts and spares available at all times.

- Lowest power consumption per quintal lint ginned

- Fully machined dynamically balanced fly wheel / machine pulley.

- All rotating parts are precision machined using advanced manufacturing process on CNC machines providing best finish & Tolerances to provide enhanced life of the machine & zero down time.

- Mechanism requiring lower periodic maintenance & setting of the machine.

- Box Spanner, M12 & M16, T Spanner M10, 1/8” BSP Threaded T Spanner, Beater Adjustment Gauge.

- Foundation Templates, Foundation Bolts, Motor Rails, Motor Pulley, Guard For Pulley, V Belts, Seed Screw Conveyor, Roll Press, Roll Cutting Stand, Cotton Bag, Weighing Stand, Lint Filling Platform, Bus Bar Panel With All Required Fittings, Platform Structure, Complete Range Of Spares, Doffer Roller Assembly, Automatic Roll Grooving Machine, Electrical Motor & Electricals.

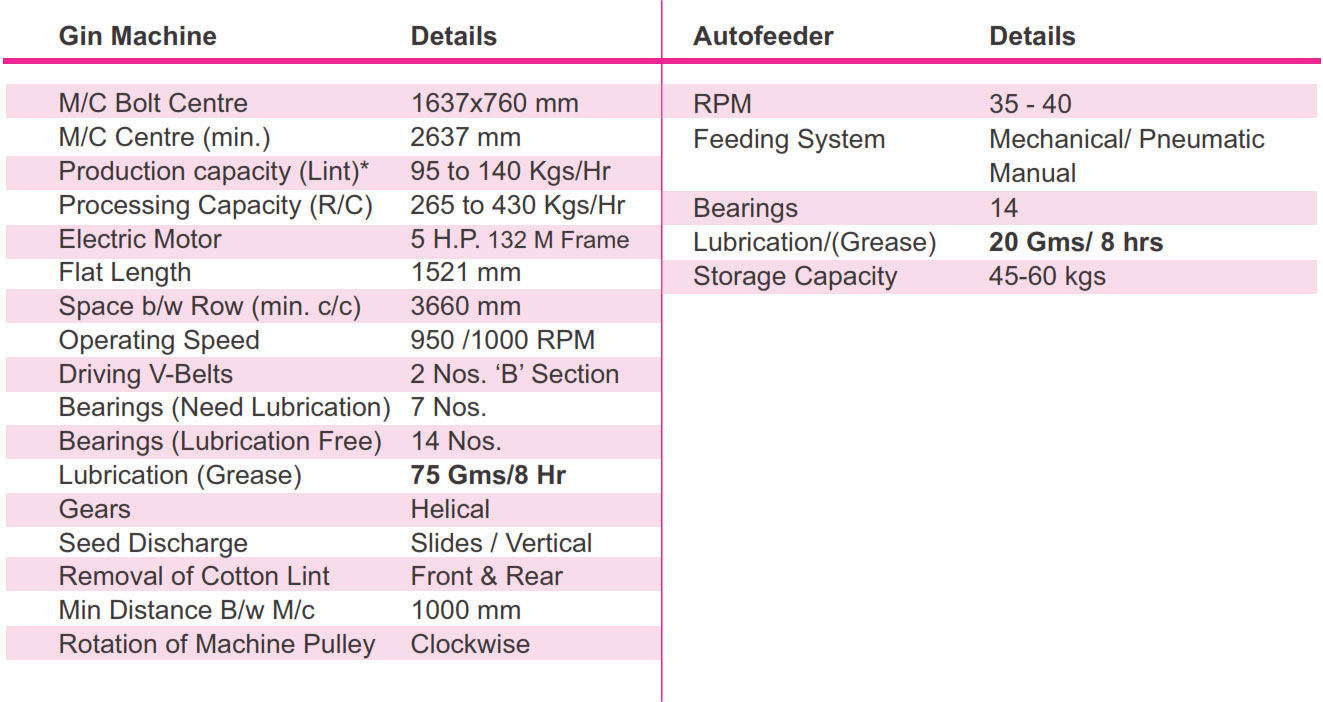

Technical Specifications