Ginning Machinery

Leading Manufacturers, Exporters, Wholesaler, Retailer of 161 Saw Gin Cotton Ginning Machine, 2000 Extractor Feeder, 201 Saw Gin Cotton Ginning Machine, 24-D Lint Cleaner Machine, 40 Saw Gin Cotton Ginning Machine, Centrifugal Lint Cleaner, Cotton Module Feeding System, Model 9000 Extractor, Model 9120 Extractor, Model 9300 Up Packing Bale Press, Model 9500 Down Packing Cotton Baling Press, Suction Command Seed Cotton Feeding System and Super III Stick Machine from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Capacity | 15 bales per hour |

| Saw | 16in dia, 161 saw blades, 615 rpm |

| Doffing Brush | 15 inch dia, 20 rows of brushes, 1552 rpm |

| Seed Roll Box | 5 inch steel tube rotates at 270 rpm, 4 inch conveyor rotates at 854rpm |

| Gin Motor | (Not included with machine) 150hp,1800 rpm, 60Hz |

| Length (front, with covers) | (3873mm) 152-1/2 in |

| Height (floor to bottom of feeder) | (1343mm) 52-7/8 in |

| Width (with covers) | (2330mm) 91-3/4 in |

| Saw Shaft centerline to floor | (730mm) 28-3/4 in |

| Weight (approximate) | (3175kg) 7000 lb |

The BAJAJ CONEAGLE Golden Eagle Series 161 Saw Gin ….can produce high quality lint at rates up to 15 bales per hour.

Featuring scientifically designed saw teeth, tempered for superstrength. The design creates less friction at the ginning point. Saws are of standard gauge and are precision ground.

- Exclusive ginning design. Patent #4313242

- A forward-tilting ginning breast allows convenient inspection of the huller ribs,

ginning ribs and roll box. - Open-end huller ribs permit high-capacity feeding of the seed roll.

- Placement of the picker roller eliminates force feeding the gin saws.

- Huller front tilts forward for accessibility to the picker rollers and the roll box. The seed roll can be easily dumped.

- Compact overall design, featuring rigid-weld steel construction.

- Optional open-end huller ribs.

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 161 saw blades mounted on a journal that rotates at 615 RPM.

The saw blades have 330Teeth and are 16 inches in diameter. Approximately 50 percent of the seed passes through holes in the patented seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Overhead MotingJet lint cleaner efficiency. Positive wiper action. No trash return. Moting can be regulated as cotton conditions dictate.

Positive Brush DoffingLint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Stainless Steel Roll BoxFeaturing self-motivated seed roll, uniform saw tooth loading, high-capacity seed discharged and automatic feed.

Seed Roll Conveyor Tube(Removes ginning seed from the center of the seed roll) This exclusive 5″ diameter louvered design rapidly removes seed. Speed of rotation is coordinated with the natural rotation of the seed roll for effective, positive results. Sealed bearing throughout.

Top Mounted Ginning RibsEngineered for safety and high performance, featuring super-strength at the ginning point. Cantilever rib design for tag relief.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Brand Name | Bajaj |

| Country of Origin | India |

| Four Spiked Cylinders | 11” diameter (279.4 mm) |

| Two Channel Saw Cylinders | 16-1/2” diameter (419.1 mm) |

| One Saw Dotter Cylinder | 11-5/8” diameter (295.2 mm) |

| Inside | 96” (2438 mm) |

| Overall with covers | 124-1/2” (3162 mm) |

Shown mounted over the Bajaj 161 Saw gin with metal guards and Polycarbonale Windows

The 2000 extractor/feeder is the economical design for fine trash removal and single locking of seed cotton fed into a gin stand. The 2000 extractor/feeder has shown excellent feeding and trash removal in field tests and in cotton High Volume Instrument testing. The model 2000’s one piece unit design will fit under most existing conveyors and in the same mounting footprint as most gin stand models. Replacement of your old feeder or any new installation with the 2000 extractor/ feeder will ensure the most economical way to feed your gin stand.

A touch screen control panel, mounted on the feeder, is used for display and changing PLC control parameters. This panel contains several touch screen displays to control every aspect of 2000 EXTRACTOR / FEEDER BAJAJ MODEL BAJAJ STEEL INDUSTRIES LTD. S I N C E 1 8 3 2 IN COLLABORATION WITH , USA Shown mounted over the Bajaj 161 Saw gin with metal guards and Polycarbonale Windows FOUR SPIKED CLEANING CYLINDERS FIVE ADJUSTABLE CLEANING GRIDS SEGMENTED HEADS FOR CYLINDER REMOVAL POLYCARBONATE GUARD WINDOWS POLYCARBONATE LINT SLIDE COVER the ginning operation. A touch screen display. with adjustable setpoints, controls capacity of ginning based upon current load on the gin motor, An AC inverter drives the 3/4 hp feed motor for ease of control and operation, The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner auto¬matically stop the ginning operation if the cotton flow is interrupted. *not included

As seed cotton enters the 200, feeder through two 6 vane feed rollers, it is first exposed to four spiked cleaning cylinders. The cotton is passed over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking.

Once through the inclined grid two section, cotton is carried to two 6-1/2” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through a combination of brushes, a control bar, and adjustable grid sections allows tor hull, stick. and fine trash removal and enhances the opening of seed cotton locks for improved ginning. A saw dotter cylinder improves single locking and transfers the seed cotton from the cleaning cylinders to the feeder apron and into the gin.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Country of Origin | India |

| Capacity | 25 bales plus per hour |

| Saw | 16″ (406mm) dia 201 saw blades, 615 rpm |

| Doffing Brush | 15 (381mm) dia. 20 rows of brushes, 1550 rpm |

| Trash Conveyor | 12″ ( 304mm) Drive 93prm |

| Seed Roll Tube | Drive 5prm steel tube roller agitator |

| Gin Motor | 250 hp |

| Picker Roller | independent drive 504 rpm |

The BAJAJ CONEAGLE EagleMax Series 201 Saw G …. can produce high quality lint at proven rates of 25 bales per hour.

- BAJAJ CONEAGLE designed ginning system equipped with the exclusive high capacity Seed Roll Conveyor Tube.

- A forward-tilting ginning breast allows convenient inspection of the ginning ribs, roll box and optional huller ribs.

- Placement of the new designed picker roller eliminates force-feeding the gin saws.

- Huller front tilts forward for accessibility to the picker roller and the roll box. The seed roll can be easily dumped.

- BAJAJ CONEAGLE 201 gin frame is equipped with a rib rail for the addition of huller ribs if cotton conditions or customer warrants their use.

- Compact overall gin design, featuring rigid-weld steel construction.

- Segmented heads for easy front removal of gin saw and gin brush.

- Optional open-end huller ribs.

Flow of Cotton

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 201 saw blades mounted on a journal that rotates at 615 RPM. The saw blades have 330-teeth and are 16 inches (406mm) in diameter. Approximately 50 percent of the seed passes through holes in the seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Positive Brush DoffingLint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Lower MotingAdjustable mote board allows for additional cleaning.

Optional Huller RibsGin Frame supplied with rib rail for optional huller rib Use.

Stainless Steel Roll BoxFeaturing selfforming seed roll, uniform saw tooth loading, high-capacity seed discharge and automatic feed.

(removes ginned seed from the center of the seed roll) This exclusive 5″ (127mm) diameter

louvered design rapidly removes seed. Speed of rotation is coordinated with the natural rotation of the seed roll for effective, positive results. Sealed bearings throughout.

Engineered for safety and high performance, featuring super-strength at the ginning point. Cantilever rib design for tag relief.

16" Gin SawsFeaturing scientifically designed and heat tempered saw teeth The design creates less friction at the ginning point. Saws are of standard gauge and are preision ground, mounted on a 6 7/8″ {174.6 mm} diameter Saw Shaft with 4 7/16· (112.7 mm) Pillow Block Bearings.

Brush & Saw RemovalSegmented heads for easy front removal of gin saw and gin brush.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand | Bajaj |

| 24-D Motor | 40hp, 1750rpm |

| Brush Cylinder | 17.75 in, cylinder dia, 1655 rpm |

| Saw Cylinder | 24.0 in, cylinder dia, 908 rpm |

| Condenser Drum | 24.0 in, cylinder dia, 27.51 rpm with Step Cone Sheave 5.0 |

| Mote Air Requirement (Per Machine) | 4000 cfm |

| Brush Air Requirement (Per Machine) | 7100 cfm |

The BAJAJ CONEAGLE Golden Eagle 24 – D Lint Cleaner produces the highest capacity and grade of any lint cleaner in the industry. Without sacrificing quality or turn-out.

The BAJAJ CONEAGLE 24-D Golden Eagle Lint Cleaner is a saw-type, controlled-batt lint cleaner having two main assemblies, the lint cleaner base and the condenser assembly mounted on top of the lint cleaner base. One optional three-phase AC motor powers all drives in the condenser and lint cleaner.

Major components of the condenser assembly consist of a 24-inch diameter perforated screen condenser drum and two grooved doffing rollers. Each end of the condenser drum is connected to an air duct. Air carrying cotton into the drum escapes out the air ducts while the cotton adheres to the drum. Adjustable flapper values

on the ducts provide air balance.

Major components of the lint cleaner base assembly consist of three feed rollers, a feed bar, eight cleaning grid bars, a saw cylinder and the doffing brush. Adjustments are provided for maintaining proper position of the components.

Single or TandemThe BAJAJ CONEAGLE Golden Eagle 24-D’s are easily installed in single unit or tandem arrangements behind any gin stand and will more than meet every challenge. Valve configuration allows use of either, neither or both lint cleaners.

Flow of CottonLint enters the condenser and is formed into a batt on the condenser screen. Air carrying the lint passes through the screen on the drum and exits out the two end ducts. The two grooved doffing rollers remove the batt from the condenser and direct it to feed rollers in the lint cleaner. The rear grooved doffing roller is installed with a minimum running clearance from the drum and allows the doffing rollers to form a pressure seat at the discharge point. The front doffing roller is set at 3/8 inch from the condenser drum. As the flow continues, the increased speed of the rollers draw and straighten fibers for the saw.

Rollers draw and direct the batt to the feed rollers and the feed bar which feeds the batt into the saw. The feed roller is under spring tension exerting a force toward the face of the feed bar. The feed roller and feed bar grip the batt so that the fibers are drawn and combed as they are placed on the surface of the saw.

Trash and mote particles thrown to the outside edge of the cotton by centrifugal force are stripped by the cleaning grid bars. The saw carries the cotton to the doffing point where it is removed by the brush. The brush also generates air flow to help convey the lint.

- 102” length handles all high capacity gins.

- Super-effcient 24″ diameter condenser

- 8 Precision machined and polished grid bars.

- Fine adjustment for top grade cleaning

- Precision engineered feed mechanism for optimum combing action

- Time-proven brush doffing

- Lock-out controls are standard equipment

- Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

- Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

- Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

- Heavy steel shafts on sealed bearings

- Easily-removed components

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| 24-D Motor | 40hp, 1750rpm |

| Brush Cylinder | 17.75 in, cylinder dia, 1655 rpm |

| Saw Cylinder | 24.0 in, cylinder dia, 908 rpm |

| Condenser Drum | 24.0 in, cylinder dia, 27.51 rpm with Step Cone Sheave 5.0 |

| Mote Air Requirement (Per Machine) | 4000 cfm |

| Brush Air Requirement (Per Machine) | 7100 cfm |

| Inside Heads | (2591mm) 102 in |

| Outside of Closed Doors | (3721mm) 146-1/2 in |

| Outside of Open Doors | (5182mm) 204 in |

| Width (Outside of Covers) | (1626mm) 64 in |

The BAJAJ CONEAGLE Golden Eagle Series 40 Saw Gin …can produce high quality lint at rates up to 3-5 balesr per hour

- Exclusive ginning design.

- A forward-tilting ginning breast allows convenient inspection of the huller ribs, ginning ribs and roll box.

- Open-end huller ribs permit high-capacity feeding of the seed roll.

- Placement of the picker roller eliminates force feeding the gin saws.

- Huller front tilts forward for accessibility to the picker rollers and the roll box. The seed roll can be easily dumped.

- Compact overall design, featuring rigid-weld steel construction.

- Optional open-end huller ribs.

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 40 saw blades mounted on a journal that rotates at 615 RPM.

The saw blades have 330

Teeth and are 16 inches in diameter. The seed is purged from the bottom pf the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Overhead MotingJet lint cleaner efficiency. Positive wiper action. No trash return. Mounting can be regulated as cotton conditions dictate

Positive Brush DoffingLint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Super Capacity and Cleaning- 102” length handles all high capacity gins.

- Super-effcient 24″ diameter condenser

- 8 Precision machined and polished grid bars.

- Fine adjustment for top grade cleaning

- Precision engineered feed mechanism for optimum combing action

- Time-proven brush doffing

- Lock-out controls are standard equipment

- Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

- Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

- Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

- Heavy steel shafts on sealed bearings

- Easily-removed components

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Discharge Vaccum | 2 in. (51 mm) WGNEG Air |

| Velocity | 12,000 Ft./min. (3658 M/min) |

| Mote Opening | Variable, Set 1 Inch (25.4 Mm) At Factory |

| Length Inside | 96 in. (2438 mm) |

| Overall | 120 in. (3048 mm) |

| Width | 62-1/8 in. (1578 mm) |

| Height | 45-1/2 in. (1156 mm) |

| Weight (approximate) | 2500 lb. (1134 kg) |

| Brand | Bajaj |

The Centrifugal Lint Cleaner is a flow-through (air-jet type) lint cleaner. Ginned lint is conveyed by air into the cleaner through a constricting duct at a relatively high velocity.

Air and cotton moving through the inlet duct make an abrupt change in direction as they pass across an adjustable mote opening. The heavier trash is ejected through the operating by inertial forces while lint is carried through the cleaner by the airstream.

The amount of trash removed is controlled by the size of the adjustable mote opening. This opening can be adjusted during operation by a handwheel on the exterior of the machine. An external graduated scale having numbers 0 through 10 provides an adjustment reference point. Ejection of trash can be observed through a window on each end or through the door on the front. In the event of a tag forming in the constricting duct, a lever is provided on top of the cleaner to quickly move the mote opening to the full open position.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Specialities | Long Life, High Performance, Easy To Operate |

| Country of Origin | India |

| Machine Structure | Horizontal |

| Brand Name | Bajaj |

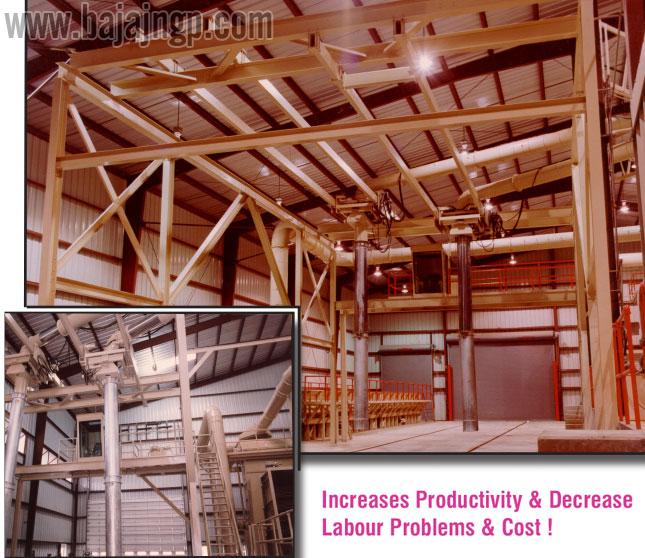

The Bajaj Module Feeder controls the volume of seed cotton conveyed dispersed and fed into the gin and is limited only by the maximum seed cotton feeding capacity of the gin machinery.

The dual drive system allows modules to be quickly conveyed to the dispersing section of the feeder. The conveyor feeding the disperser has a variable speed drive to coordinate the module flow with the capacity of the gin plant. Additional 36’ conveyor sections may be added to increase module storage capacity.

The Company manufactures moving floor feeders, moving head feeders, dump feeders, belt feeders and roller feeders and has been proven the best for feeding all types of module seed cotton into the ginning system.

The new customer requested cost saving Bajaj Module Feeder design features the same proven components of our Standard Module Feeder with only one section of walkways and no module side walls.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weight | (5670 Kg) 12,500 Lb. |

| Extractor-feeder Motor | 15 Hp, 1800 Rpm or from Gin (not Included with Machine) Saw Shaft |

| Feed Motor | 3/4 HP, 1800 RPM, 230/460 volt, 3-phase 60 Hz, TEFC Frame 56C (wire for 230 volt) |

| Gear Reducer | Grant, 30:1 Ratio, Stf 225 Worm Gear W/standard Length Shaft |

| Four Saw Cylinders | 16 1/2″ Od, 95 5/8 Long, 160 Saws 5/8″ Wide |

| Two Doffing Cylinders | 11 5/8″ Od, 95 5/8″ Long |

| Two Feed Cylinders | 5 3/4″ Od, 95 5/8″ Long, 6 Vanes |

| Four Spiked Cylinders | (ls-1) 110 Volt, 30 Mm, 3/16″ Sensing Distance, Led, 9 Sec. Start Up Delay |

| Length Inside | (2438 Mm) 96 In. |

| End of Shafts | (3276 mm) 129 in. |

| Overall (with covers) | (3657 mm) 144 in. |

| Height | (2337 mm) 92 in. |

| Width : Front to Back Rear Doors Closed | (2426 mm) 95 1/2″ |

Designed for improved fine trash removal and enhanced single locking. This BAJAJ CONEAGLE Golden Eagle feeder has shown superb test results in all areas of its application. The Model 9000 is the result of an extensive research and development program and on-site testing.

A push-button control panel, mounted on the feeder, controls feeder load or ginning rate and may also be operated from the master console. This panel contains eight annuciator lights for indicating status of the ginning operation. An AC inverter drives the 3/4 hp feed motor for ease of control and operations. A dual set point meter controls capacity of inning through current load on the gin motor. The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner automatically stop the ginning operation if the cotton flow is interrupted. The standard drive for the Model 9000 is a 15 hp, 1800 rpm motor*.

Flow of Cotton

As seed cotton enters the Model 9000, it is first exposed to four spiked cleaning cylinders. The cotton passes over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking. These spiked cylinders are the same type as used in our 96″ BAJAJ CONEAGLE Impact Cleaner.

Once through the inclined grid section, cotton is carried to four 16 ½” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through the tested combinations of brushes, control bars and grid sections allows for excellent hull, stick and additional fine trash removal and further enhances the opening of seed cotton locks for improved ginning. Two doffing cylinders transfer the seed cotton from cleaning cylinders to the feeder apron.

Maintenance Considerations

Lockable, hinged fiberglass covers provide a clean design while allowing access to drives, bearings and adjustment points. The covers need only be opened, not completely removed, for repairing cylinders and other components. Segmented heads allow each cylinder to be removed independently without completely disassembling the machine.

Other features include 5 ½” glass windows in the heads to aid adjusting brushes, grids, control bars and doffers. Two full width rectangular windows on front of the feeder allow viewing the flow of seed cotton.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Extractor/Feeder Motor | (not included with machine) 25 hp, or from Gin Saw Shaft |

| Feed Motor | 3/4 hp |

| Gear Reducer | 30:1 Ratio |

| Four Saw Cylinders | 16″ ½” 00 (419.1mm),119 1/2” long (3035mm) |

| Two Doffing Cylinders | 11 5/8″ (295.3mm) 00, 119 1/2″ long (3035mm) |

| Two Feed Cylinders | 6 Vanes 5 3/4″ (146mm) 0D, 119 ½” long (3035mm) |

| Four Spiked Cylinders | 11″ (279mm) 00, 119 ½” Long (3035mm) |

| Motion Detector | (LS-1) 3/16″ (4.76mm) sensing distance, LED, 9 sec. start up delay |

The BAJAJ CONEAGLE EagleMax Series 9120 Extractor/Feeder …. can process and feed seed cotton at proven rates of 25 bales per hour.

Designed for improved fine trash removal and enhanced single locking. This EagleMax Extractor/Feeder has shown superb test results in all areas of its application. The Model 9120 is the result of an extensive research and development program and on-site testing.

A touch screen control panel. mounted on the feeder, controls feeder load or ginning rate and may also be operated from the master console. This control display contains status of ginning operation. An AC inverter drives the 3/4hp feed motor for ease of control and operation. A touch screen dual set point controls capacity of ginning through current load on the gin motor. The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detctors on the feeder and lint cleaner automatically stop the ginning operation if the cation flow is interrupted. The standard drive for the Model 9120 is a 25 hp, motor*.

Maintenance Considerations

Lockable, hinged Metal Covers with viewing windows provide a clean design while allowing access to drives, bearings and adjustment points. The covers need only be opened, not completely removed, for repairing cylinders and other components. Segmented heads allow each cylinder to be removed independently without completely disassembling the machine.

Other features include 5 1!2″ (139.7mm) glass viewing ports in the heads to aid in adjusting brushes, grids, control bars and doffer cylinders. Two full width rectangular windows on front of the feeder allow viewing the flow of seed cotton.

Flow of Cotton

As seed cotton enters the Model 9120 Extractor! Feeder, it is first exposed to four spiked cleaning cylinders. The cotton passes over the top of the cylinders and is conveyed between the cylinders and inclined grid bar section. This action allows improved fine trash removal and single locking of the seed cotton. These four spiked cleaning cylinders are the same type cylinders used in our 120″ (3048mm) Impact Cleaner.

Once through the inclined grid section, seed cotton is carried to four 161/2″ (419mm) channel saw cylinders, one of which functions as a reclaimer. the flow of cotton through the tested combinations of brushes, control bars and grid sections allows for excellent hull, stick and additional fine trash removal and further enhances the opening of seed cotton locks for improved ginnlng. Two doffing cylinders transfer the seed cotton from cleaning cylinders to the feeder apron.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Driven Type | Electric |

| Country of Origin | India |

| Application | Commercial/Industrial |

| Machine Grade | Automatic, Semi-Automatic |

| I Deal In | New Only |

| Material | Mild Steel |

A Signode bale strapping unit is shown. Other types of bale strapping systems are available by customer choice.

- The 9300 Press is the Industry’s only-fiber bale press capable of pressing 80 universal density bales per hour.

- Designed to operate with several optional plastic and wire bale strapping systems.

- Tramper speeds up to 20 strokes per minute.

Main Press Pumping Unit : 1200 gallons (4540 liters)

Pump Motors : 100 Hp, 230/460 v, 3ph

#1 Press Booster : 100 Hp, 230/460 v, 3ph

Tramper / Pusher : 100 Hp, 230/460 v, 3ph

Pump / Filter Unit : 5.4 Hp, 230/460/380 v, 3ph ( 60 Hz Motors = 1800 rpm)

Pumps : Vane and Piston

Hydraulic Tank : 1200 gallons (4540 liters) removable top service doors

Booster Pumping Unit : 400 gallons (1513 liters)

Pump Motors : 100 Hp, 1800 rpm,230/460 v, 3ph

#2 Press Booster : 100 Hp, 230/460 v, 3ph

#2 Tramper Booster : 100 Hp, 230/460 v, 3ph

Pump/Filter Unit : 5.4 Hp, 230/460/380 v, 3ph ( 60 Hz Motors = 1800 rpm)

Pumps : Vane and Piston

Hydraulic Tank : 400 gallons (1513 liters) removable top service door

Rotator / Unlocking Pumping Unit

Hydraulic Tank : 20 gallons

Pump Motor : 15 hp, 230/460v, 3ph

Pump : 1.37 cu.in./rev (22.45 cu.cm./rev) Gear-Submerged

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Type | Cotton Baling Press |

| Country of Origin | India |

| Application | Press the ginned cotton in individual bale |

| Size | High Density, Universal Density, Customised Bale Sizes |

| Automatic Grade | Automatic |

| Power Consumption | Based On No. of Bales and Bale Size |

Two Capacity Options Available 45 Bales Per Hour And 60 Bales Per Hour.

- Universal Density 20”X54” (.508m X 1.3716m)

- High Density 20” X 41” (.508m X 1.0414m)

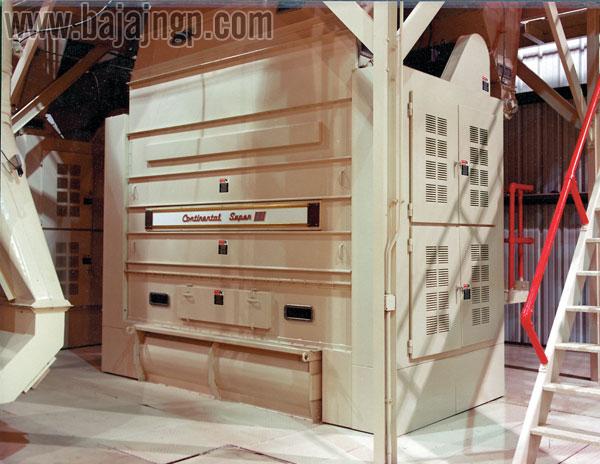

The Continental Eagle Model 9500 slip box down-packing press is capable of baling cotton up to 55 bales per hour and is similar in design to the successful 950 press. The 9500 press uses less connected horsepower and is 3’-3” (.9906 m) shorter than the 950 press. The 9500 press is available in both a universal density 20” X 54” at 28 pounds/cubic foot (.508 m x 1.3716 m) at 12.7008 kg/cubic meter and a high-density 20” X 41” at 32 pounds/cubic foot (.508 X 1.0414 m) at 14.5152 kg/cubic meter) bale size model. The 9500 is designed to press at a capacity that would be sufficient to handle two or three high capacity gin stands in a cotton ginning facility.

Dimensions

The overall height of the 9500 press is 28’- 2 5/8” (8.6011 m). Press dogs are designed into the boxes to hold the cotton in the box when the boxes are rotated. A 11’ X 20’ (3.3528 m X 6.096 m) work/access platform surrounds the front and rear of the press with an access ladder or optional stairs. The pusher has a 49-inch (1.2446 m) tall face and a 2’/2-inch (6.35 cm) diameter by 54-inch (6.4516 m) stroke hydraulic cylinder. The hydraulic control block for the pusher has a unique feature that takes the pusher out of “regenerative mode” toward the end of the extend stroke. This feature increases the available force (4000 pounds @ 800 psi) (1.8144 mt @ 5161.28 cm2) to push the cotton charge into the charge box under the tramper. Ultra high molecular weight (UHMW) and special ceramic UHMW are used on all wear surfaces. The tramper cylinder length is 102 inches (2.5908 m) with a 6-inch (15.24 cm) diameter to reduce operating pressure. UHMW blocks are used on the guide rods. The two ram cylinders have a length of 80 inches (2.0320 m) with 10 inch (25.4 cm) diameters. Two press rams are used for a more even distribution of force when pressing a bale. The hydraulic system utilizes a single 750 gallon (2839.05 Liters) vertical tank design. The ram pump is a high volume piston pump with a operating pressure of 5800 psi (37419.28 cm2). Vane pumps are used on the tramper, stripper, pusher, and auxiliary components. Pressure filter safeguards are used on several hydraulic lines for contaminant removal. The 9500 press is PLC controlled. Pushbuttons for every press operation are located on the face of the console for instant control access. The press console uses a touch screen for monitoring pressures, making operational adjustments and troubleshooting. Pressure sensitive switch mats come standard and cover the full rotational area when the press boxes rotate.

Several bale handling options are available. An automatic bale cart and bagging system and a retractable bale conveyor and bagging system.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Bajaj |

| Power Source | Electric |

| Application | Cotton Ginning |

| Country of Origin | India |

| Material | Mild Steel |

| Features | Rustproof, Corrosion Resistance |

Electro –Hydraulic Controlled Suction System for Cotton Modules, Wagons & Bulk Seed Cotton

The Suction –Command System takes the worry out of finding dependable labour for suction feeding seed cotton from your trailers or modules. The standard system consists of two lanes independent suction lanes. Bajaj’s Suction – Command System can be designed to meet your individual needs from one to four suction lanes.

Unlimited directional control is smooth and easy. The steel carriage assembly and the high strength aluminium telescopes are very responsive to the operator’s controls.

Swing Momentum is always under control by the operator. The Suction Command operator cab is a clean , comfortable environment.

6 MAJOR DESIGN FEATURES

- Engineered for Strength with Less Weight.

Stronger design in critical areas, yet total weight saved reduces wear and strain on track rails and entire structure.

- Thick Walled Aluminium Telescopes

Stronger Tubes with less weight give better control and put less stress on the swing mechanism.

- Flexible Swivel Sleeve

A positive, air tight fit provides efficient operation and requires minimum maintenance.

- Large Radius Elbows

Choking is virtually eliminated

- Four Rubber Covered Carriage Wheels

All wheels are powered delivering positive traction. Traverse travel is straight… no binding.

- Industrial Grade Hydraulic Cylinders

Other Feature

- Hydraulic Power Cylinders

- Long Life Constructions

- Case Hardened Piston Rods

- Four Traversing Motors Per Unit

- Independent H beam Support Frame and Bracing

- All four carriage wheels are powered by the highest quality Hydraulic Traversing Motors

- Tapered Pistons Provide Cushion to reduce Shock

Instantly available power when demanded and power cost savings when there is no demand.60 gallons ( 227.2 Litre) Fluid Capacity

15 gallons ( 56.8Litre) Per minute

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Brand | Bajaj |

| Model | 48” / 60” / 72” / 96″ / 120” |

| Application | Industrial |

| Size | Customize |

Unequaled for bulk removal of sticks, hulls and leaves from machine picked or stripped cotton.

Shown with 24” vacuum – Vacuum, ductwork, and supports are not included with the Super III

The Super III is unequalled for bulk removal of sticks, hulls and leaves from machine picked or stripped cotton. Cotton entering the machine is directed to two large extracting cylinders and a third saw cylinder cleans and reclaims excess cotton from the main cleaning cylinders.

The efficient extraction of foreign matter greatly reduces the wear and damage to other ginning equipment.

The Super III is the practical, performance proven machine for better cleaning at high capacity and producing quality sample on all types of cotton.

The Super III installed in the gining plant assures more effective and efficient operation of the machinery processes that follow. it is designed to operate at capacities equal to the overall installation requirements.

Profit – Making Features :

- Super III sling-off action assures no restriction of cotton flow for high capacity.

- Super III can be installed in existing gin outfit with minimum engineering and rearrangement.

- Continental Eagle precision manufactured temperhardended channel saws on dynamically balanced cylinders.

- Wire brushes set cotton on saw cylinders.

- Bar grids designed for more effective stick removal-easily adjusted to saw.

- High speed doffing cylinders remove cotton from 16″ saw cleaning cylinders.

- Lower saw cylinder reclaims cotton-cleans as effectively as upper cylinders.

- Two large doors on back of Super III provide easy access for maintenance.

- Metal doffers for long life.

- Minimum maintenance.

- Built-in by-pass for cleanly picked cotton.