- GST No. 27AAACB5340H1ZY

- Send SMS

- Send Email

Ginning & Pressing

Leading Manufacturers, Exporters, Wholesaler, Retailer of 161 Saw Gin, 2000 Extractor Saw Gin, 201 Saw Gin, 24-D Lint Cleaner, 40 Saw Gin, Air Lock, Air Separator, Air Separators, Battery Condenser, Bucket Elevator, Centrifugal Lint Cleaner, Cotton Bale Wire Ties, Cotton Boll Opener, Cotton Ginning Machine Magnum Model, Cotton Ginning Machine Platina Models, Cotton Ginning Machine Tejas Model, Cotton Module Feeding System, Down Packing Cotton Baling Press, DOWN PACKING COTTON BALING PRESS 9500 MODEL, Fully Automatic Ginning Plant, Ginning Machine Auto Feeder, Impact Cleaner, Lint Cleaner, Model 9000 Extractor, Model 9120 Extractor, Model 9500 Down-Packing Press, Overflow Hopper, Pneumatic Conveying System, Raw Cotton Horizontal Pre Cleaner, Raw Cotton Pre Cleaner, Screw Conveyor, Seed cotton dispensing system, Stone Catcher, Stone Remover Cum Hot Box, Suction Command Seed Cotton Feeding System, Super III Stick Machine, Surge Hopper, Twin Auto Regulator and Vertical Flow Drier from Nagpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Capacity | 15 Bales per Hour |

| Saw | 16in Dia, 161 Saw Blades, 615 Rpm |

| Doffing Brush | 15 Inch Dia, 20 Rows of Brushes, 1552 Rpm |

| Seed Roll Box | 5 Inch Steel Tube Rotates At 270 Rpm, 4 Inch Conveyor Rotates At 854rpm |

| Gin Motor | (Not included with machine) 150hp,1800 rpm, 60Hz |

| Length (front, with Covers) | (3873mm) 152-1/2 in |

| Height (floor to Bottom of Feeder) | (1343mm) 52-7/8 in |

| Width (with Covers) | (2330mm) 91-3/4 in |

| Saw Shaft Centerline to Floor | (730mm) 28-3/4 in |

| Weight (approximate) | (3175kg) 7000 lb |

Preferred Buyer From

| Location | Worldwide |

Featuring scientifically designed saw teeth, tempered for superstrength. The design creates less friction at the ginning point. Saws are of standard gauge and are precision ground.

- Exclusive ginning design. Patent #4313242

- A forward-tilting ginning breast allows convenient inspection of the huller ribs,

- ginning ribs and roll box.

- Open-end huller ribs permit high-capacity feeding of the seed roll.

- Placement of the picker roller eliminates force feeding the gin saws.

- Huller front tilts forward for accessibility to the picker rollers and the roll box. The seed roll can be easily dumped.

- Compact overall design, featuring rigid-weld steel construction.

- Optional open-end huller ribs.

Flow of Cotton

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 161 saw blades mounted on a journal that rotates at 615 RPM.

The saw blades have 330

Teeth and are 16 inches in diameter. Approximately 50 percent of the seed passes through holes in the patented seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Overhead Moting

Jet lint cleaner efficiency. Positive wiper action. No trash return. Moting can be regulated as cotton conditions dictate.

Positive Brush Doffing

Lint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Stainless Steel Roll Box

Featuring self-motivated seed roll, uniform saw tooth loading, high-capacity seed discharged and automatic feed.

Seed Roll Conveyor Tube

(Removes ginning seed from the center of the seed roll) This exclusive 5″ diameter louvered design rapidly removes seed. Speed of rotation is coordinated with the natural rotation of the seed roll for effective, positive results. Sealed bearing throughout.

Top Mounted Ginning Ribs

Engineered for safety and high performance, featuring super-strength at the ginning point. Cantilever rib design for tag relief.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Feeder Motor (not Included with Machlne)….15 Hp, 1800 Rpm (60 Cycle) | 15 Hp, 1500 Rpm (50 Cycle) or No Motor Used When Driven from the Gin Saw Shaft |

| Feed Roller Motor | 3/4 HP, 1800 RPM, 230/460 Volt, 3-phase 60Hz TEFC Frame, 56C (wire for 230 volt) |

| Four Spiked Cylinders | 11” Diameter (279.4 Mm) |

| Two Channel Saw Cylinders | 16-1/2” Diameter (419.1 Mm) |

| One Saw Dotter Cylinder | 11-5/8” Diameter (295.2 Mm) |

| Two Feed Cylinders | 5-3/4” Diameter (146 Mm) |

| Length Inside | 96” (2438 mm) |

| Overall with Covers Height Cover Top to Bottom | 6’ 3-7/8” (1952.6 mm) |

| Top of Cover to Bottom of Head Height | 9’ 1/4” (2749.5 mm) |

| Width Front of Touch Screen to Back | 7’ 7/8” (2155.8 mm) |

| Approximate (without guards)Weight | 7,340 lbs (3329.4 kg) |

Preferred Buyer From

| Location | Worldwide |

The 2000 extractor/feeder is the economical design for fine trash removal and single locking of seed cotton fed into a gin stand. The 2000 extractor/feeder has shown excellent feeding and trash removal in field tests and in cotton High Volume Instrument testing. The model 2000’s one piece unit design will fit under most existing conveyors and in the same mounting footprint as most gin stand models. Replacement of your old feeder or any new installation with the 2000 extractor/ feeder will ensure the most economical way to feed your gin stand.

A touch screen control panel, mounted on the feeder, is used for display and changing PLC

control parameters. This panel contains several touch screen displays to control every aspect of 2000 EXTRACTOR / FEEDER BAJAJ MODEL BAJAJ STEEL INDUSTRIES LTD. S I N C E 1 8 3 2 IN COLLABORATION WITH , USA Shown mounted over the Bajaj 161 Saw gin with metal guards and Polycarbonale Windows FOUR SPIKED CLEANING CYLINDERS FIVE ADJUSTABLE CLEANING GRIDS SEGMENTED HEADS FOR CYLINDER REMOVAL POLYCARBONATE GUARD WINDOWS POLYCARBONATE LINT SLIDE COVER the ginning operation. A touch screen display. with adjustable setpoints, controls capacity of ginning based upon current load on the gin motor, An AC inverter drives the 3/4 hp feed motor for ease of control and operation, The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner auto¬matically stop the ginning operation if the cotton flow is interrupted. *not included

As seed cotton enters the 200, feeder through two 6 vane feed rollers, it is first exposed to four spiked cleaning cylinders. The cotton is passed over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking.

Once through the inclined grid two section, cotton is carried to two 6-1/2” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through a combination of brushes, a control bar, and adjustable grid sections allows tor hull, stick. and fine trash removal and enhances the opening of seed cotton locks for improved ginning. A saw dotter cylinder improves single locking and transfers the seed cotton from the cleaning cylinders to the feeder apron and into the gin.

Features :

- Four Spiked Cleaning Cylinders

- Five Adjustable Cleaning Grids

- Segmented Heads for Cylinder Removal

- Polycarbonate Guard Windows

- Polycarbonate Lint Slide Cover

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Capacity | 25 Bales Plus per Hour |

| Saw | 16″ (406mm) Dia 201 Saw Blades, 615 RPM |

| Doffing Brush | 15 (381mm) Dia. 20 Rows of Brushes, 1552 Rpm |

| Seed Roll Tube | Independent Drive 5″ (127mm) Steel Tube Rotates At 270 Rpm, 4′ (101.6mm) Conveyor Rotates At 854 Rpm |

| Gin Motor | (Not Included with Machine) 250 HP |

| Picker Roller | Independent Drive 350 Rpm |

| Length (front, with covers) | (4470 mm) 176” |

| Height (floor to Bottom) | (1343 mm) 52 7/8” of feeder) |

| Width (with Covers) | (2383 mm) 93 13/16” |

| Saw Shaft Centerline | (730 Mm) 28 3/4”to Floor |

| Weight (approximate) | (3628 Kg) 8000 Lb |

Preferred Buyer From

| Location | Worldwide |

Product Details :

- BAJAJ CONEAGLE designed ginning system equipped with the exclusive high capacity Seed Roll Conveyor Tube.

- A forward-tilting ginning breast allows convenient inspection of the ginning ribs, roll box and optional huller ribs.

- Placement of the new designed picker roller eliminates force-feeding the gin saws.

- Huller front tilts forward for accessibility to the picker roller and the roll box. The seed roll can be easily dumped.

- BAJAJ CONEAGLE 201 gin frame is equipped with a rib rail for the addition of huller ribs if cotton conditions or customer warrants their use.

- Compact overall gin design, featuring rigid-weld steel construction.

- Segmented heads for easy front removal of gin saw and gin brush.

- Optional open-end huller ribs.

Flow of Cotton

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 201 saw blades mounted on a journal that rotates at 615 RPM. The saw blades have 330-teeth and are 16 inches (406mm) in diameter. Approximately 50 percent of the seed passes through holes in the seed tube located in the center of the roll box where they are conveyed to the ends of the gin and discharged to the seed conveyor below the gin. The remaining seed is purged from the bottom of the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Positive Brush Doffing

Lint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Lower Moting

Adjustable mote board allows for additional cleaning.

Optional Huller Ribs

Gin Frame supplied with rib rail for optional huller rib Use.

Stainless Steel Roll Box

Featuring selfforming seed roll, uniform saw tooth loading, high-capacity seed discharge and automatic feed.

Seed Roll Conveyor Tube

(removes ginned seed from the center of the seed roll) This exclusive 5″ (127mm) diameter

louvered design rapidly removes seed. Speed of rotation is coordinated with the natural rotation of the seed roll for effective, positive results. Sealed bearings throughout.

Top Mounted Ginning Ribs with Inserts

Engineered for safety and high performance, featuring super-strength at the ginning point. Cantilever rib design for tag relief.

16" Gin Saws

Featuring scientifically designed and heat tempered saw teeth The design creates less friction at the ginning point. Saws are of standard gauge and are preision ground, mounted on a 6 7/8″ {174.6 mm} diameter Saw Shaft with 4 7/16· (112.7 mm) Pillow Block Bearings.

Brush & Saw Removal

Segmented heads for easy front removal of gin saw and gin brush.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| 24-D Motor | 40hp, 1750 RPM |

| Brush Cylinder | 17.75 In, Cylinder Dia, 1655 Rpm |

| Saw Cylinder | 24.0 In, Cylinder Dia, 908 Rpm |

| Condenser Drum | 24.0 in, cylinder dia, 27.51 rpm with Step Cone Sheave 5.0 |

| Mote Air Requirement (Per Machine) | 4000 CFM |

| Brush Air Requirement (Per Machine) | 7100 CFM |

| Length Inside Heads | (2591mm) 102 in |

| Length Outside of Closed Doors | (3721mm) 146-1/2 in |

| Length Outside of Open Doors | (5182mm) 204 in |

| Length Width (Outside of Covers) | (1626mm) 64 in |

| Floor to top of Condenser | (2657mm) 104-5/8 in |

| Floor to top Horizontal Duct | (3442mm) 135-1/2 in |

| Condenser Weight | (1069kg) 2,400 lbs |

| Lint Cleaner Base Weight | (3656kg) 8,060 lbs |

Preferred Buyer From

| Location | Worldwide |

The BAJAJ CONEAGLE 24-D Golden Eagle Lint Cleaner is a saw-type, controlled-batt lint cleaner having two main assemblies, the lint cleaner base and the condenser assembly mounted on top of the lint cleaner base. One optional three-phase AC motor powers all drives in the condenser and lint cleaner.

Major components of the condenser assembly consist of a 24-inch diameter perforated screen condenser drum and two grooved doffing rollers. Each end of the condenser drum is connected to an air duct. Air carrying cotton into the drum escapes out the air ducts while the cotton adheres to the drum. Adjustable flapper values

on the ducts provide air balance.

Major components of the lint cleaner base assembly consist of three feed rollers, a feed bar, eight cleaning grid bars, a saw cylinder and the doffing brush. Adjustments are provided for maintaining proper position of the components.

Single or Tandem

The BAJAJ CONEAGLE Golden Eagle 24-D’s are easily installed in single unit or tandem arrangements behind any gin stand and will more than meet every challenge. Valve configuration allows use of either, neither or both lint cleaners.

Flow of Cotton

Lint enters the condenser and is formed into a batt on the condenser screen. Air carrying the lint passes through the screen on the drum and exits out the two end ducts. The two grooved doffing rollers remove the batt from the condenser and direct it to feed rollers in the lint cleaner. The rear grooved doffing roller is installed with a minimum running clearance from the drum and allows the doffing rollers to form a pressure seat at the discharge point. The front doffing roller is set at 3/8 inch from the condenser drum. As the flow continues, the increased speed of the rollers draw and straighten fibers for the saw.

Rollers draw and direct the batt to the feed rollers and the feed bar which feeds the batt into the saw. The feed roller is under spring tension exerting a force toward the face of the feed bar. The feed roller and feed bar grip the batt so that the fibers are drawn and combed as they are placed on the surface of the saw.

Trash and mote particles thrown to the outside edge of the cotton by centrifugal force are stripped by the cleaning grid bars. The saw carries the cotton to the doffing point where it is removed by the brush. The brush also generates air flow to help convey the lint.

Super Capacity and Cleaning

- 102” length handles all high capacity gins.

- Super-effcient 24″ diameter condenser

- 8 Precision machined and polished grid bars.

- Fine adjustment for top grade cleaning

- Precision engineered feed mechanism for optimum combing action

- Time-proven brush doffing

- Lock-out controls are standard equipment

- Rugged, Trouble-Free Construction

- Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

- Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

- Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

- Heavy steel shafts on sealed bearings

- Easily-removed components

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| 24-D Motor | 40hp, 1750RPM |

| Brush Cylinder | 17.75 in, Cylinder Dia, 1655 RPM |

| Saw Cylinder | 24.0 In, Cylinder Dia, 908 RPM |

| Condenser Drum | 24.0 in, cylinder dia, 27.51 rpm with Step Cone Sheave 5.0 |

| Mote Air Requirement (Per Machine) | 4000 CFM |

| Brush Air Requirement (Per Machine) | 7100 CFM |

| Inside Heads | (2591mm) 102 in |

| Outside of Closed Doors | (3721mm) 146-1/2 in |

| Outside of Open Doors | (5182mm) 204 in |

| Width (Outside of Covers) | (1626mm) 64 in |

| Floor to top of Condenser | (2657mm) 104-5/8 in |

| Floor to top Horizontal Duct | (3442mm) 135-1/2 in |

| Condenser | (1069kg) 2,400 lbs |

| Lint Cleaner Base | (3656kg) 8,060 lbs |

Preferred Buyer From

| Location | Worldwide |

Product Details :

- Exclusive ginning design.

- A forward-tilting ginning breast allows convenient inspection of the huller ribs, ginning ribs and roll box.

- Open-end huller ribs permit high-capacity feeding of the seed roll.

- Placement of the picker roller eliminates force feeding the gin saws.

- Huller front tilts forward for accessibility to the picker rollers and the roll box. The seed roll can be easily dumped.

- Compact overall design, featuring rigid-weld steel construction.

- Optional open-end huller ribs.

Lint is pulled and separated from the cotton seed by the gin saw rotating between ginning ribs. The saw teeth carry the lint through the evenly spaced ginning ribs at the ginning point and the seed is left behind in the roll box. The saw consists of 40 saw blades mounted on a journal that rotates at 615 RPM

The saw blades have 330

Teeth and are 16 inches in diameter. The seed is purged from the bottom pf the seed roll and falls into the seed conveyor. Lint is removed from the saw by the doffing brush.

Overhead Moting

Jet lint cleaner efficiency. Positive wiper action. No trash return. Mounting can be regulated as cotton conditions dictate

Positive Brush Doffing

Lint is removed directly from the gin saws at super-capacities producing a smooth sample. Features positive lint discharge and adjustable air intake.

Super Capacity and Cleaning

- 102” length handles all high capacity gins.

- Super-effcient 24″ diameter condenser

- 8 Precision machined and polished grid bars.

- Fine adjustment for top grade cleaning

- Precision engineered feed mechanism for optimum combing action

- Time-proven brush doffing

- Lock-out controls are standard equipment

Rugged, Trouble-Free Construction

- Precision machined feed plate, adjustable for accurate placement, heavily built to hold critical settings

- Exclusive concave grid bar design further straightens and aligns fibers for high trash removal with reduced lint loss

- Exclusive tooth design on wire-wrapped saw insured superior lint retention, easier doffing

- Heavy steel shafts on sealed bearings

- Easily-removed components

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Salient Features :

- Discharges material efficiently with air back pressure.

- Heavy duty construction; longer life.

- Made with superior technical know how.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Max opening for efficient material discharge.

- Robust construction

- Made with superior technical know how

- Less space required

- Low maintenance

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Salient Features :

- Efficient and Gentle separation of material (Seed Cotton & Lint) from air.

- Optimizes ginning per formance.

- Robust construction; longer life.

- Made with superior technical know how.

- Available in different models with different feeding systems for specific requirements.

- Removes dust, fine trash & short fibres to good extent.

- Max suction area for extracting air from material and efficient material discharge at the bottom.

- Robust Body

- Simple Operations

- Easy Maintenance

- Interchangeability of Spares

- Less Power Consumption

- Higher Output

- Higher Profits

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Finishing | Powder Coated |

| Machine Weight | Customised |

| Packaging Type | Customised |

| Pressure | Customised |

| Usage | Cotton Industry |

| Specialities | Customised |

| Dimension (LxWxH) | Customised |

| Type | Air Separator |

| Brand Name | Bajaj |

| Material | Mild Steel |

| Shape | Customised |

| Certification | ISO 9001:2008 Certified |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Power | Customised |

| Driven Type | Hydraulic |

| Connection Type | Customised |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Corrosion Resistance | Yes |

| Operating Type | Automatic |

| Thickness | Customised |

| Operating Temperature | Customised |

| Frequency | Customised |

| Production Capacity | 15 |

| Accuracy | Customised |

| After-Sales Service Provided | Yes |

| Flow Rate | Customised |

| Noise Level | Customised |

| Payment Terms | D/A |

| Delivery Time | 7 Days |

Preferred Buyer From

| Location | Worldwide |

To furnish the diverse requirements of our clients we are involved in manufacturing, supplying and exporting a wide range of Air Separator with Vacuum Wheel. These are manufactured using best quality material which we sourced from the trusted and reliable vendors of the market. These have spiked cleaning cylinders across individual round grid bars ensure gentle treatment and a free flow of seed - cotton through the machine, an adequate opening of cotton and removal of all fine trash including dust, sand, leaf, pepper, and pin before they get embedded in the cotton.

Features:

- Robust Body

- Simple Operations

- Easy Maintenance

- Interchangeability of Spares

- Less Power Consumption

- Higher Output

- Higher Profits

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Capacity / Hour (avg) | 5000 Kgs of Lint |

| Power (Max) | 5 HP |

| Height | 2100 mm |

| Width | 2250 mm |

| Length | 2180 mm |

| Weight (approx) | 2000 Kg |

| Drum Diameter | 40” |

| Optional Accessories | I) VFD drive for 5HP motor, II) Panel for VFD |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Even formation of the lint batt for the press.

- All rotating parts are provided with anti friction bearings for optimum efficiency.

- Easy to maintain; Low maintenance cost.

- High quality wooden rafters for doffing rollers adds to the life of roller.

- High density Nylon gears used for motion transmission reduces maintenance and optimize smooth functioning.

- Swinging arms provided to all 4 rollers reduce the thrust and allow better compression of all density lint.

- Even formation of the lint batt for the press.

- Optimizes pressing performance

- Made with superior technical know how

- Robust Construction

- Protects fibre quality

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Bajaj Bucket Elevators are ideally suited to elevate bulk materials from sluggish to free flowing vertically. These bucket elevators are manufactured for capacities up to 15000 Kg/hr. depending upon the material requirements. Bajaj Bucket Elevators consists of rectangular rigid mild steel housing with a tangential inlet in the bottom section and an inclined outlet in the top section. Bajaj Bucket Elevators are of centrifugal type with rigid seamless mild steel buckets mounted on open ended belts. These are anti static oil repellent in nature. The drive unit comprises of an electrical motor coupled to reduction gear box mounted on the maintenance platforms attached to the top section.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Discharge Vaccum | 2 in. (51 mm) WGNEG Air |

| Velocity | 12,000 Ft./min. (3658 M/min) |

| Mote Opening | Variable, Set 1 Inch (25.4 Mm) At Factory |

| Length Inside | 96 in. (2438 mm) |

| Overall | 120 in. (3048 mm) |

| Width | 62-1/8 in. (1578 mm) |

| Height | 45-1/2 in. (1156 mm) |

| Weight (approximate) | 2500 lb. (1134 kg) |

Preferred Buyer From

| Location | Worldwide |

The Centrifugal Lint Cleaner is a flow-through (air-jet type) lint cleaner. Ginned lint is conveyed by air into the cleaner through a constricting duct at a relatively high velocity.

Air and cotton moving through the inlet duct make an abrupt change in direction as they pass across an adjustable mote opening. The heavier trash is ejected through the operating by inertial forces while lint is carried through the cleaner by the airstream.

The amount of trash removed is controlled by the size of the adjustable mote opening. This opening can be adjusted during operation by a handwheel on the exterior of the machine. An external graduated scale having numbers 0 through 10 provides an adjustment reference point. Ejection of trash can be observed through a window on each end or through the door on the front. In the event of a tag forming in the constricting duct, a lever is provided on top of the cleaner to quickly move the mote opening to the full open position.

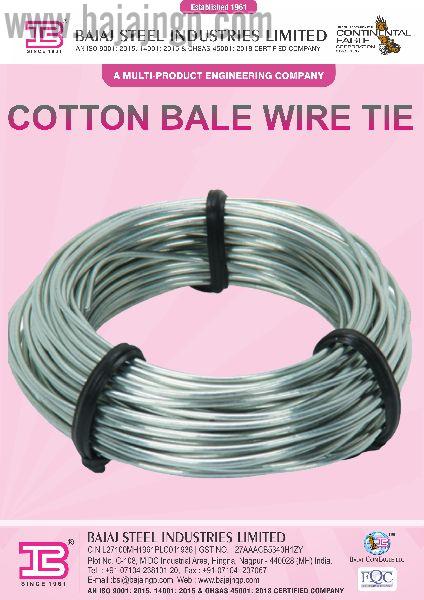

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Wire Ties |

| Material | Galvanised |

| Thickness | Customised |

| Length | Customised |

| Application | Bales Tie |

| Color | Silver |

| Feature | Excellent Strength, Good Quality, High Griping, Rust Resistance, Weather Resistance |

| Finishing | Polished |

| Wire Gauge | Customised |

| Country of Origin | India |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- High quality galvanized wire

- Easy to feed , bend and tie

- Designed effectively for break load, tensile and elongations and hence highly reliable

- Available for all bale densities

- Double loop for strong locking

- High strength

- High reliability

- Suitable for high/universal density bales

- Made from special steel

- Rust proof

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Cleaning Capacity / Hour(avg) | 600 Kgs Raw Cotton |

| Connected Total Power | 5 HP |

| Height from Top of Hopper | 5 1/4’ |

| Height from Top of Cover | 4 1/4’ |

| Width | 3 ½’ |

| Length | 12’ |

| Weight (approx) | 750 Kgs |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Movable

- Easy to operate

- Fully automatic

- Robust construction

- Maximizes profits

An additional profit machine :

- Designed to open raw cotton bolls by air turbulence and clean lower grades of cotton by separating dust, leaves immature bolls etc.

- Most efficient for cleaning zoda, leafy and other lower grades of raw cotton as well as collection from pre-cleaners.

- Reduces manpower required for sorting, by allowing dust, leaves and immature bolls to fall below through grids with holes of different sizes for separate collection.

- Opened and cleaned raw cotton delivered at the discharge-end

- Recovers useful raw cotton from trash cotton collections.

- No damage to cotton fibre in the process.

Robust Construction :

- A large capacity fan is provided before inlet to create sufficient air pressure to aerate raw cotton by air turbulence.

- Large diameter beaters are provided to separate dust, leaves and immature bolls etc. and push the clean raw cotton towards the discharge-end.

- The grids are made of heavy- gauge steel sheets.

- The round holes of different- size grids do not get clogged easily.

- The top cover of the machine is of painted cr sheets to make the machine weather- resistant.

- The main shaft runs on three heavy-duty ball bearing encased in dust- proof housing to give trouble free service for number of years, with lower power consumption.

Safe and Trouble free :

- Guarding at the feed-end as well as at the discharge-end has been provided for safety purpose.

- Totally enclosed by sheet metal with door to collect trash & pre-matured bolls separately.

- Suitable base for fitting electric motor has been provided to eliminate slide rails.

- The covers of the machine are tightened by fly-nuts to enable the operator to attend the machine without using spanner.

- Driving arrangement is totally enclosed.

Optional Accessories

- Wheel arrangement

- Elelctric motor

- Transmission pulley & belt

- Starter

- Switch

- Heavy-duty,four core flexible cable

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Roller Ginning Machines |

| Certification | ISO 9001:2008 |

| Application | Cotton cleaning |

| Weight | Customised |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Rated Power | Customised |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Warranty | 1year |

| Country of Origin | India |

| M/C Bolt Centre | 1637x760 mm |

| M/C Centre (min.) | 2637 mm |

| Production capacity (Lint)* | 95 to 140 Kgs/Hr |

| Processing Capacity (R/C) | 265 to 430 Kgs/Hr |

| Electric Motor | 5 H.P. 132 M Frame |

| Flat Length | 1521 mm |

| Space b/w Row (min. c/c) | 3660 mm |

| Operating Speed | 950 /1000 RPM |

| Driving V-Belts | 2 Nos. ‘B’ Section |

| Bearings (Need Lubrication) | 7 Nos. |

| Bearings (Lubrication Free) | 14 Nos |

| Lubrication (Grease) | 75 Gms/8 Hr |

| Gears | Helical |

| Seed Discharge | Slides / Vertical |

| Removal of Cotton Lint | Front & Rear |

| Min Distance B/w M/c | 1000 mm |

| Rotation of Machine Pulley | Clockwise |

| Autofeeder RPM | 35 - 40 |

| Feeding System | Mechanical/ Pneumatic Manual |

| Bearings | 14 |

| Lubrication/(Grease) | 20 Gms/ 8 hrs |

| Storage Capacity | 45-60 kgs |

| Payment Terms | D/A |

| Delivery Time | 7 Days |

Preferred Buyer From

| Location | Worldwide |

Highest out Turn of Lint than other Ginning System. Cleaner Seeds with minimum Cotton Linter on it.

We have been awarded the “Largest and modern cotton ginning & pressing machinery manufacturer in India” by the hands of then Hon’ble Union minister of textile Govt. of India Mr. Shankersinh Vaghela.

Why MAGNUM DR ?

- Increased leather roll diameter

- 14 sealed / Pre greased bearings

- Only 3 greasing points

- Improved beater housing for easy setting

- Adequate weights on leather roll for higher production

- Use of superior material for highest strength of spare parts

- About 50% lower vibration

- Magnum Machine design is compatible for use of normal greasing bearing as all 2RS bearing area has provision for fitment & use of normal greasing bearing (in emergency case)

- Highest production in same size DR Machines

- Less Power Consumption per unit of production

- One to one replacement on Golden Jubilee/ Ultra models

- Less man power as less greasing points

- Longer wear life of leather roller

- Interchangeability of spares

- Significantly higher profits

- Robust body

- Simple operations

- Lustrous lint fiber production Machine

- Improved autofeeder for better performance

- Prompt after sales service

Over 100,000 Bajaj Double Roller Ginning Machines are operating throughout India and various other countries like Bangladesh, Egypt, Indonesia, Kenya, Madagascar, Myanmar, Nepal, Nigeria, Peru, Shri Lanka, Tanzania, Uganda, Zambia, Zimbabwe etc.

BENEFITS

- Protects Fibre Quality ; Gives Production of Clean ; Lustrous Cotton Lint.

- Works efficiently ; reduces cost and Adds to profitability.

- Engineering experiences and expertise combined to ensure lowest operational and maintenance cost.

- Consumes less power.

- All gears, connecting rod, head, beater arm, swing lever etc. are made of high Nodularity ductile iron.

- All rotating parts are provided with precision bearings to reduce friction for optimum efficiency.

- Connecting housing is provided with heavy duty self aligning roller bearing.

- Leather roller shafts are interchangeable and if one side of the roller is worn out, It can be reversed.

- Lint output remains uniform on full length of the rollers.

- Moving parts are housed in dust proof gear box for smooth running.

- Lubrication is pressure fed, dust proof greasing system.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Roller Ginning Machines |

| Certification | ISO 9001:2008 |

| Application | Cotton cleaning |

| Weight | Customised |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Rated Power | Customised |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Warranty | 1year |

| Country of Origin | India |

| Size | 54″ |

| M/C Bolt Centre | 1477 x 760 mm |

| M/C Centre (min.) | 2357 mm |

| Production Capacity (Lint)* | 75 to 110 Kgs/Hr |

| Processing Capacity (R/C)* | 225 to 330 Kgs/Hr |

| Electric Motor | 5 H.P. 132 S Frame |

| Flat Length | 1361mm |

| Space b/w Row (min. c/c) | 3350 mm |

| Operating Speed | 950 / 1000 RPM |

| Driving V-Belts | 2 Nos. ‘B’ Section |

| Bearings (Need Lubrication) | 7 Nos. |

| Bearings (Lubrication Free) | 14 Nos. |

| Lubrication (Grease) | 20 Gms/8 Hrs |

| Gears | Helical |

| Seed Discharge | Slides / Vertical |

| Removal of Cotton Lint | Front & Rear |

| Min Distance B/w M/c | 880 mm |

| Rotation of Machine Pulley | Clock Wise |

| Autofeeder R.P.M. | 35 - 40 |

| Feeding System | Mechanical / Pneumatic / Manual |

| Autofeeder Bearings | 14 Nos |

| Storage Capacity | 42 - 55 kg |

| Payment Terms | D/A |

| Delivery Time | 7 Days |

Preferred Buyer From

| Location | Worldwide |

Bajaj Double Roller Gin Machine - PLATINA, a New Generation model in 54' with Highest Strength and Highest Output in its range along with advanced Autofeeder having only three Greasing points with 50% lesser vibrations. Capable to Gin the maximum strength seed cotton upto 50 G/Tex with Lustrous Lint fiber production, uses less power consumption per unit of production.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Roller Ginning Machines |

| Certification | ISO 9001:2008 |

| Application | Roller Cutting |

| Weight | Customised |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Rated Power | Customised |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Warranty | 1year |

| Country of Origin | India |

| M/C Bolt Centre | 1477x760mm |

| M/C Centre (min) | 2357 mm |

| Production Capacity( Lint) | 65 to 105 Kgs/Hr |

| Processing Capacity (R/C) | 200 to 265 Kgs/Hr |

| Electric Motor | 5 H.P 132 S Frame |

| Flat Length | 1361 mm |

| Space b/w Row (min c/c) | 3350mm |

| Operating Speed | 950/1000 RPM |

| Driving V-Belts | 2 Nos/B Section |

| Bearings (Need Lubrication) | 5 Nos. |

| Bearings (Lubrication Free) | 16 Nos. |

| Lubrication (Grease) | 75 Gms/8 Hrs |

| Gears | Helical |

| Seed Discharge | Vertical |

| Removal of Cotton Lint | Front & Rear |

| Min Distance B/w M/c | 880 mm |

| Rotation of Machine Pulley | Clock Wise |

| Autofeeder R.P.M. | 35 - 40 |

| Feeding System | Mechanical / Pneumatic / Manual |

| Autofeeder Bearings | 10 Nos. (Lubrication Free), 4 Nos. (Need Lubrication) |

| Autofeeder Lubrication (grease) | 20 Gms/8 Hrs |

| Autofeeder Storage Capacity | 42 - 55 kg |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Bajaj DR gins give highest out turn of lint with better seed quality at lowest maintenance and per unit cost of production. Highest out Turn of Lint than other Ginning Systems. Cleaner Seeds with minimum Cotton Linter on it.

Application areas:

- Cotton industry

Features:

- Higher productivity

- High-quality output

- Less downtime

- Efficient removal of dust and trash

- Lowest cost of production per unit in the industry

- Lower power consumption per quintal of lint ginned

- Lower manpower required

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

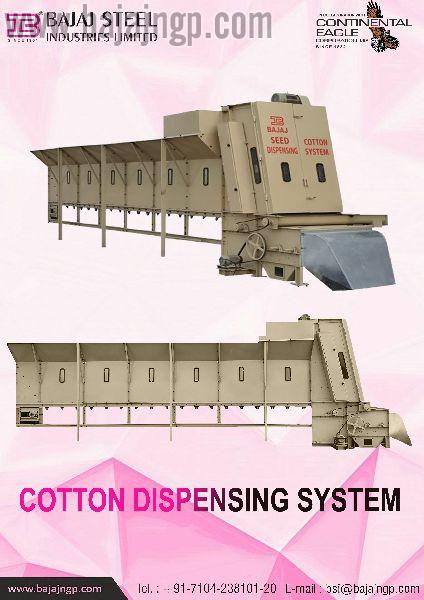

The Bajaj Module Feeder controls the volume of seed cotton conveyed dispersed and fed into the gin and is limited only by the maximum seed cotton feeding capacity of the gin machinery.

The dual drive system allows modules to be quickly conveyed to the dispersing section of the feeder. The conveyor feeding the disperser has a variable speed drive to coordinate the module flow with the capacity of the gin plant. Additional 36’ conveyor sections may be added to increase module storage capacity.

The Company manufactures moving floor feeders, moving head feeders, dump feeders, belt feeders and roller feeders and has been proven the best for feeding all types of module seed cotton into the ginning system.

The new customer requested cost saving Bajaj Module Feeder design features the same proven components of our Standard Module Feeder with only one section of walkways and no module side walls.

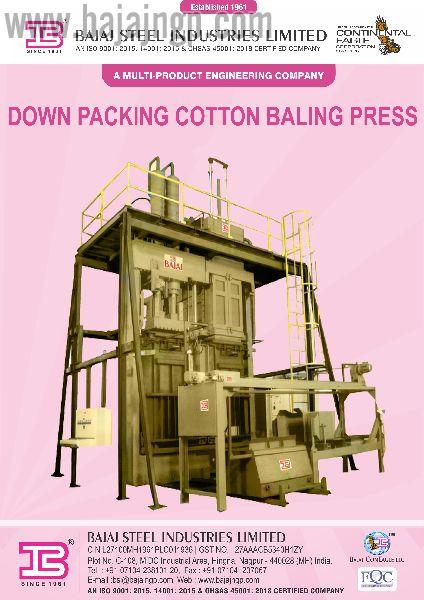

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Cotton Baling Press |

| Certification | ISO 9001:2008 |

| Application | Cotton Pressing |

| Weight | Customised |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | Customised |

| Driven Type | Hydraulic |

| Warranty | 1year |

| Type | Cotton Baling Press |

| Country of Origin | India |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Bajaj Steel is a leading company involved in manufacturing, supplying and exporting a wide range of Fully Automatic/Semi Automatic Down Packing Cotton Bailing Presses which has bailing capacity of 5,8,10,15,20,25,30,35,45 & 60 Bales Per Hour.

Application areas

- Cotton industry for cotton pressing

Features

- Double box press

- High-speed automatic revolving of boxes

- Low power consumption

- Low maintenance

- Lowest packaging & manpower requirements

- High-pressure power pack

- Doorless mechanism

- Down packing without any underground pit

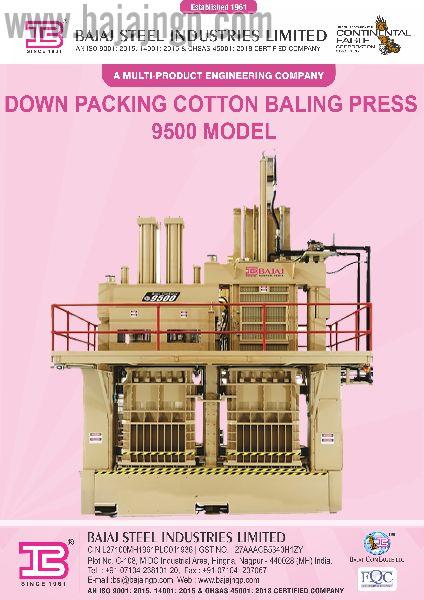

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Certification | ISO 9001:2008 |

| Weight | Customised |

| Automatic Grade | Automatic |

| Warranty | 1year |

| Voltage | 380V |

| Country of Origin | India |

| Brand Name | Bajaj |

| Application | Hydraulic |

| Color | Tan |

| Condition | New |

| Power | Customised |

| Driven Type | Customised |

| Pressure | Customised |

| After-Sales Service Provided | Yes |

| Production Capacity | 2 |

| Certificate | Yes |

| Press (Complete)Weight | 89,300 lbs. (40506 Kgs.) |

| Upper Beam Weight | 11,060 lbs. (5016 Kgs.) |

| Lower Beam Weight | 15,900 lbs. (7211 Kgs. |

| Upper Ram Weight | 2,900 lbs. (1315 Kgs.) |

| Lower Ram Weight | 9,900 lbs. (4490 Kgs.) |

| 9300 Press “20”X41” | 11,900 lbs. (5490 Kgs.) 9300 Press |

| Lower Box 9300 Press “20”X41” | 11,900 lbs. (5490 Kgs.) 9300 Press |

| Lower Box “20X54” | 12,070 lbs. (5474 Kgs.) |

| Upper Follower Block 9300 Press “20X41’” | 2,100 lbs. (954 Kgs.) |

| 9300 Press “20X54” | 2,330 lbs. (1057 Kgs.) |

| End Column | 3,420 Lbs. (1551 Kgs.) |

| Center Column Assembly | 3,450 lbs. (1565 Kgs.) |

| Ram Casing | 5,715 lbs. (2592 Kgs.) |

| Pusher | 2,840 lbs. (1288 Kgs.) |

| Capacity | Maximum 80+ Bales per Hour (with Optional Equipment) |

| Lower Ram | 18 In. Dia X 121 In. Stroke. Maximum Force Output Approximate 636 Tons |

| Upper Ram | 12 In.bore X 8 1/2 In. Rod X 58 In. Stroke Maximum Force Output Approximate 200 Tons |

| Tramper Cylinder | 6 In. Bore X 4 In. Rod X 132 in Working Stroke |

| Pusher Cylinder | 2 ½ in Bore X 1 3/4 in Rod X 54 in Working Stroke. |

| Belt Feeder Motor RPM | 360-400 |

| Pump Displacement | 5.4 cu.in/rev. (88.5 cu./rev) |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

The BAJAJ CONEAGLE Model 9300 up-packing fiber bale press is capable of pressing 50 to 80 universal density bales per hour. The standard 9300 press has a capacity of 50 bales per hour with the standard 1200 gallon hydraulic pumping unit (305 connected HP) and one 20 gallon rotator/lock hydraulic pumping unit (15 HP). An additional 400 gallon Booster pumping unit (135 connected HP) is required to produce 60 bales per hour. When the 9300 press is equipped with an optional high speed pumping and tramping / Pusher system this press has consistently run at speeds of 75 to 80 + bales per hour.

An 18 inch diameter x 121 inch stroke lower ram and a 12 inch diameter x 44 inch stroke upper ram are used to compress the lint cotton into a universal density bale. The force output of the lower ram is approximately 636 tons (577 metric tons).The force output of the upper ram is approximately 200 tons (181 metric tons). The 9300 press is equipped with a hydraulic pusher and tramper. The hydraulic pusher feeds lint cotton into one press box and the hydraulic tramper vertically packs the cotton charge into the box at speeds of up to 20 strokes per minute. A hydraulic rotator motor rotates the press boxes 180 degrees for further packing of the lint cotton by the press rams into a universal density bale.

The 9300 press may be operated in an automatic or semi-automatic mode. In the automatic mode, the press operates fully automatic when an automatic bale tying device is used. If the press is used in a semiautomatic mode the press operator pushes the ram down button on the press console to initiate the bale eject sequence after manual bale tying is finished. Press operations are controlled by a Programmable Logic Controller (PLC) in the press console. The control console contains the control electronics, press systems monitoring indicators, and controls for all operations of the press.

Hydraulic power for operation of the Model 9300 is supplied by electric motor driven pumps installed on one or two reservoirs. The primary reservoir for the mid capacity presses holds 1200 gallons of hydraulic oil. The optional booster pump unit holds 400 gallons of hydraulic oil. Piston and vane pumps supply oil to hydraulic control blocks for distribution to the pusher/belt feed, tramper, upper and lower rams circuits.The main pumping units are interconnected in one hydraulic tank. The reservoirs have removable service doors located on the tank top. A visual oil level gauge is provided on each reservoir. The tank interiors are baffled and braced to separate intake ports from return ports. A separate gear pump with a dedicated oil reserve supplies oil to the rotator, and box unlock circuits. each pumping unit utilizes a dedicated filter/cooler pump that pumps oil through a screw-on type filter to either an oil/air or and oil/water cooler.

Main Press Pumping Unit : 1200 gallons (4540 liters)

Pump Motors : 100 Hp, 230/460 v, 3ph

#1 Press Booster : 100 Hp, 230/460 v, 3ph

Tramper / Pusher : 100 Hp, 230/460 v, 3ph

Pump / Filter Unit : 5.4 Hp, 230/460/380 v, 3ph ( 60 Hz Motors = 1800 rpm)

Pumps : Vane and Piston

Hydraulic Tank : 1200 gallons (4540 liters) removable top service doors

Booster Pumping Unit : 400 gallons (1513 liters)

Pump Motors : 100 Hp, 1800 rpm,230/460 v, 3ph

#2 Press Booster : 100 Hp, 230/460 v, 3ph

#2 Tramper Booster : 100 Hp, 230/460 v, 3ph

Pump/Filter Unit : 5.4 Hp, 230/460/380 v, 3ph ( 60 Hz Motors = 1800 rpm)

Pumps : Vane and Piston

Hydraulic Tank : 400 gallons (1513 liters) removable top service door

Rotator / Unlocking Pumping Unit

Hydraulic Tank : 20 gallons

Pump Motor : 15 hp, 230/460v, 3ph

Pump : 1.37 cu.in./rev (22.45 cu.cm./rev) Gear-Submerged

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Cotton Ginning Machine |

| Certification | ISO 9001:2008 |

| Application | Cotton Cleaning |

| Weight | 100-1000kg |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Driven Type | Electric |

| Warranty | 1year |

| Country of Origin | India |

| Payment Terms | D/A |

Preferred Buyer From

| Location | Worldwide |

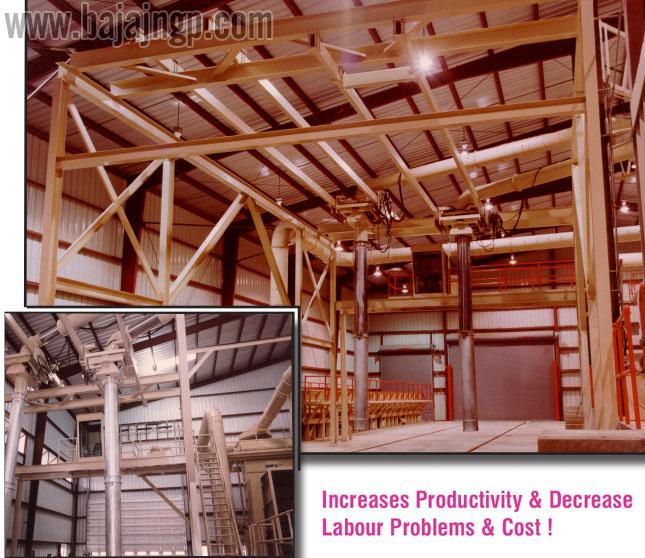

Bajaj Steel Provides Fully Automatic Ginning plants are most advanced in the industry where we provide Pre Cleaners, Post Cleaners, Conveying Systems, Automatic Feeding Systems, Overflow Handling, Feed Regulators and PLC’s to synchronize and control many of the processes.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- No Extra Electricity.

- Saves man power/ Considerable saving in labour cost.

- Easy to maintain; Low maintenance cost.

- No need to disassemble the Auto Feeder for machine maintenance.

- No need to disassemble the Auto Feeder for changing Auto Feeder cloth.

- Increases productivity between 15% to 20%.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Features :

- Heavy Steel Construction

- Sealed Bearings Throughout

- Spiked Drums on full length shafts

- Brush Doffer

- Serrated Discs made of Saw Steel

- Positive serpentine Drive…Endless Belt…idlers to adjust tension and tracking

- Minimum Maintenance

- Maintains gentle action while cleaning…no scrubbing that produces fiber damage.

- Spiked and serrated discs give rapid change of direction to dislodge trash.

- Tips f 11-1/2″ (292.10 mm) serrated discs form a revolving grid system under spiked rollers. Each disc is keyed to shaft having space blocks between and are locked in place by a threaded shaft with a large retaining nut.

- Trash is dropped free of cotton travel path.

- Reclaimer section has grid areas to clean reclaimer locks before returning them to the cotton stream.

- Reclaimer is adjustable for all types of cotton… prevents loss, yet permits maximum cleaning.

- 96″ (2438.40 mm) and 120″ (3048.00 mm) Impacts have 5 spiked rollers and 5 disc rollers.

- Sealed ball bearings throughout.

- Shipping weight (approximate) :

- 96″ – 9,300 lbs. (4,0824 kg.)

- 120″ – 12,000 lbs. (5,4432 kg.)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Removes seeds coats, leafy matter after ginning.

- Improves lint grade & appearance.

- Reduces trash content & other contamination.

- Eliminates micro-dust effectively.

- Precise design preserves fiber properties.

- Removes short fiber clusters from ginned lint.

- Better quality lint yields higher returns.

- Easy to maintain; Low maintenance cost.

- Available in different models with different feeding systems for specific requirements.

- Can be incorporated in pneumatic conveying system for online cleaning.

- Considerable saving in labour cost.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Extractor-feeder Motor | 15 Hp, 1800 Rpm or from Gin (not Included with Machine) Saw Shaft |

| Feed Motor | 3/4 HP, 1800 RPM, 230/460 volt, 3-phase 60 Hz, TEFC Frame 56C (wire for 230 volt) |

| Gear Reducer | Grant, 30:1 Ratio, Stf 225 Worm Gear W/standard Length Shaft |

| Four Saw Cylinders | 16 1/2″ Od, 95 5/8 Long, 160 Saws 5/8″ Wide |

| Two Doffing Cylinders | 11 5/8″ Od, 95 5/8″ Long |

| Two Feed Cylinders | 5 3/4″ Od, 95 5/8″ Long, 6 Vanes |

| Four Spiked Cylinders | (ls-1) 110 Volt, 30 Mm, 3/16″ Sensing Distance, Led, 9 Sec. Start Up Delay |

| Length Inside | (2438 Mm) 96 In. |

| End of Shafts | (3276 mm) 129 in. |

| Overall (with covers) | (3657 mm) 144 in. |

| Height | (2337 mm) 92 in. |

| Width : Front to Back Rear Doors Closed | (2426 mm) 95 1/2″ |

| Weight | (5670 Kg) 12,500 Lb. |

Preferred Buyer From

| Location | Worldwide |

Designed for improved fine trash removal and enhanced single locking. This BAJAJ CONEAGLE Golden Eagle feeder has shown superb test results in all areas of its application. The Model 9000 is the result of an extensive research and development program and on-site testing.

A push-button control panel, mounted on the feeder, controls feeder load or ginning rate and may also be operated from the master console. This panel contains eight annuciator lights for indicating status of the ginning operation. An AC inverter drives the 3/4 hp feed motor for ease of control and operations. A dual set point meter controls capacity of inning through current load on the gin motor. The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner automatically stop the ginning operation if the cotton flow is interrupted. The standard drive for the Model 9000 is a 15 hp, 1800 rpm motor*.

Flow of Cotton

As seed cotton enters the Model 9000, it is first exposed to four spiked cleaning cylinders. The cotton passes over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking. These spiked cylinders are the same type as used in our 96″ BAJAJ CONEAGLE Impact Cleaner.

Once through the inclined grid section, cotton is carried to four 16 ½” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through the tested combinations of brushes, control bars and grid sections allows for excellent hull, stick and additional fine trash removal and further enhances the opening of seed cotton locks for improved ginning. Two doffing cylinders transfer the seed cotton from cleaning cylinders to the feeder apron.

Maintenance Considerations

Lockable, hinged fiberglass covers provide a clean design while allowing access to drives, bearings and adjustment points. The covers need only be opened, not completely removed, for repairing cylinders and other components. Segmented heads allow each cylinder to be removed independently without completely disassembling the machine.

Other features include 5 ½” glass windows in the heads to aid adjusting brushes, grids, control bars and doffers. Two full width rectangular windows on front of the feeder allow viewing the flow of seed cotton.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Extractor/feeder Motor | (not Included with Machine) 25 Hp, or from Saw Shaft |

| Feed Motor | 3/4 HP |

| Gear Reducer | 30:1 Ratio |

| Four Saw Cylinders | 16″ ½” 00 (419.1mm),119 1/2” long (3035mm) |

| Two Doffing Cylinders | 11 5/8″ (295.3mm) 00, 119 1/2″ long (3035mm) |

| Two Feed Cylinders | 6 Vanes 5 3/4″ (146mm) 0D, 119 ½” long (3035mm) |

| Four Spiked Cylinders | 11″ (279mm) 00, 119 ½” Long (3035mm) |

| Motion Detector | (ls-1) 3/16″ (4.76mm) Sensing Distance, Led, 9 Sec. Start Up Delay |

| Length Inside | (3048 mm) 120 in. |

| End of Shafts | (3711 Mm) 146 1/8 In. |

| Overall (with Cover) | (4273 Mm) 168 1/4 In. |

| Height | (2336 Mm) 92 In. |

| Width Front to Back | (2425 Mm) 95 ½ In. Rear Doors Closed |

| Weight (approximate) | (5443 Kg) 12,000 Lb. |

Preferred Buyer From

| Location | Worldwide |

Designed for improved fine trash removal and enhanced single locking. This EagleMax Extractor/Feeder has shown superb test results in all areas of its application. The Model 9120 is the result of an extensive research and development program and on-site testing.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

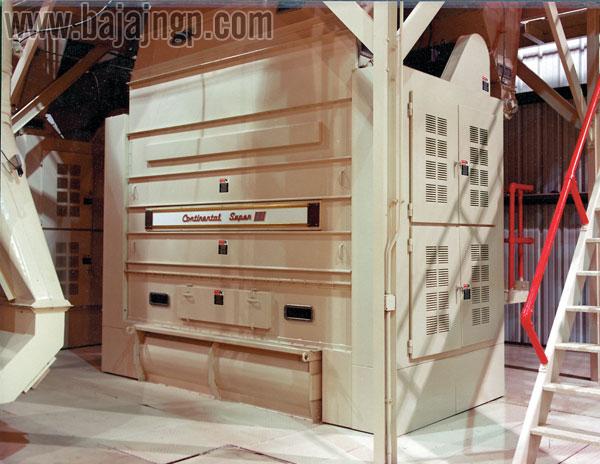

| Universal Density | 20”X54” (.508m X 1.3716m) |

| High Density | 20” X 41” (.508m X 1.0414m) |

Preferred Buyer From

| Location | Worldwide |

The Continental Eagle Model 9500 slip box down-packing press is capable of baling cotton up to 55 bales per hour and is similar in design to the successful 950 press. The 9500 press uses less connected horsepower and is 3’-3” (.9906 m) shorter than the 950 press. The 9500 press is available in both a universal density 20” X 54” at 28 pounds/cubic foot (.508 m x 1.3716 m) at 12.7008 kg/cubic meter and a high-density 20” X 41” at 32 pounds/cubic foot (.508 X 1.0414 m) at 14.5152 kg/cubic meter) bale size model. The 9500 is designed to press at a capacity that would be sufficient to handle two or three high capacity gin stands in a cotton ginning facility.

The overall height of the 9500 press is 28’- 2 5/8” (8.6011 m). Press dogs are designed into the boxes to hold the cotton in the box when the boxes are rotated. A 11’ X 20’ (3.3528 m X 6.096 m) work/access platform surrounds the front and rear of the press with an access ladder or optional stairs. The pusher has a 49-inch (1.2446 m) tall face and a 2’/2-inch (6.35 cm) diameter by 54-inch (6.4516 m) stroke hydraulic cylinder. The hydraulic control block for the pusher has a unique feature that takes the pusher out of “regenerative mode” toward the end of the extend stroke. This feature increases the available force (4000 pounds @ 800 psi) (1.8144 mt @ 5161.28 cm2) to push the cotton charge into the charge box under the tramper. Ultra high molecular weight (UHMW) and special ceramic UHMW are used on all wear surfaces. The tramper cylinder length is 102 inches (2.5908 m) with a 6-inch (15.24 cm) diameter to reduce operating pressure. UHMW blocks are used on the guide rods. The two ram cylinders have a length of 80 inches (2.0320 m) with 10 inch (25.4 cm) diameters. Two press rams are used for a more even distribution of force when pressing a bale. The hydraulic system utilizes a single 750 gallon (2839.05 Liters) vertical tank design. The ram pump is a high volume piston pump with a operating pressure of 5800 psi (37419.28 cm2). Vane pumps are used on the tramper, stripper, pusher, and auxiliary components. Pressure filter safeguards are used on several hydraulic lines for contaminant removal. The 9500 press is PLC controlled. Pushbuttons for every press operation are located on the face of the console for instant control access. The press console uses a touch screen for monitoring pressures, making operational adjustments and troubleshooting. Pressure sensitive switch mats come standard and cover the full rotational area when the press boxes rotate.

Several bale handling options are available. An automatic bale cart and bagging system and a retractable bale conveyor and bagging system.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Connected Total Power | 2 HP |

| Capacity (Kgs /Hr) of Seed Cotton | 1500 Kg |

Preferred Buyer From

| Location | Worldwide |

Benefits & Features :

- Robust Construction; Longer Life.

- Form An Integral Part of Seed Cotton Distribution System to Gins.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Programmed to handle and recycle the unused seed cotton of screw conveyor feeder for seed cotton.

- Variable feed rates for specific requirements.

- Supplied with high quality electrical accesories and dust proof sensors for efficient performance.

- Substantial savings in labour cost

- Robust construction

- Made with superior technical know how

- easily accomodated in existing setups

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Bajaj manufactures most efficient pneumatic conveying systems for cotton seed. Pneumatic conveying offers an ideal choice for transportation of seed cotton, lint, cotton seed and other materials as the material is transported in a closed pipeline which protects it from environmental contaminations and also are smooth, trouble free, time saving and cheaper for long distance transportations.

- Available in spiral and plain construction

- Higher thickness of sheets for longer life

- Heavy duty bends, diverters, expander and reducers etc.

- Well designed joining

- Efficient removal of foreign particles

Pneumatic Conveying system for seeds or Seed Blowing System is a combination of following :

Galvanised Pipes: We provide galvanised pipes from 5” dia to 36” dia for various applications these are made in length upto 6 mtr connected to each other by Flanges at the ends with suitable filler material to give leak proof joints.

Elbows or bends for vertical movement of material.

Seed Blowing Attachment:- This attachment consist of a rottary feeder with specially designed Ventury and Hopper to suit the requirement.

Roots Blower:- It is used to create positive pressure differentials to carry the seed.

Cyclones:- Bajaj cyclones designed and manufactured to seed discharge rate from Roots Blower. These cyclones are made of mild steel and are used for seed feeding to the rotary air lock above the seed bagging conveyor.

Some of the sailent features of Cyclones are as below :

- Robust Construction

- No maintenance

- Long life

Rotary Airlock:- Rotary Airlock are used to discharge trash, fibres, dust etc. below the cyclone after dust collectors without allowing air to enter into the system or for seed blowing systems to discharge seed in the conveyor below cyclone.

Rotary airlocks are also used as rotary feeder in case of cotton seed blowing systems.

Screw Conveyor for Seed Bagging :-

- Available in various sizes upto 450 mm diameter

- Efficient distribution of seed for multi point bagging

- Effective alignment for maximum length

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| No. of Cleaning Cylinders | Eight |

| Width | 1200/1500/1800 mm |

| Raw Cotton Cleaning Capacity per Hour | 3000/6000/9000 Kgs. |

| Connected Total Power | 7 H.P. / 7 H.P./ 9.5 H.P. |

| Operating Speed (at different Rollers) | 185 – 300 rpm |

| Wheel-mounting (optional) | Yes |

| Feeding System | Mechanical/ Pneumatic/ Manual |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction; longer life

- Made with superior technical know-how

- Reduces maintenance of ginning machines.

- Removes yellow/ pre-matured bolls, trash, stones and others impurities from raw cotton, there by improving the quality of raw cotton prior to ginning.

- Increases productivity of ginning machines

- Reduces load on ginning machines

- Auto feeding made easy and trouble-free

- Auto feeder maintenance reduced to minimum

- Better quality of lint yields higher returns

- Considerable saving in labour cost

- Available in different models with different feeding systems for specific requirements.

- All models can also be wheel-mounted for easy mobility.

- Trash removal can be mechanical/ manual/ pneumatic.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Protects fiber quality

- Cleans gently and efficiently

- Optimizes ginning performance

- Robust construction; longer life

- Made with superior technical know-how

- Reduces maintenance of ginning machines.

- Removes yellow/ pre-matured bolls, trash, stones and others impurities from raw cotton, there by improving the quality of raw cotton prior to ginning.

- Increases productivity of ginning machines

- Reduces load on ginning machines

- Auto feeding made easy and trouble-free

- Auto feeder maintenance reduced to minimum

- Better quality of lint yields higher returns

- Considerable saving in labor cost

- Available in different models with different feeding systems for specific requirements.

- All models can also be wheel-mounted for easy mobility.

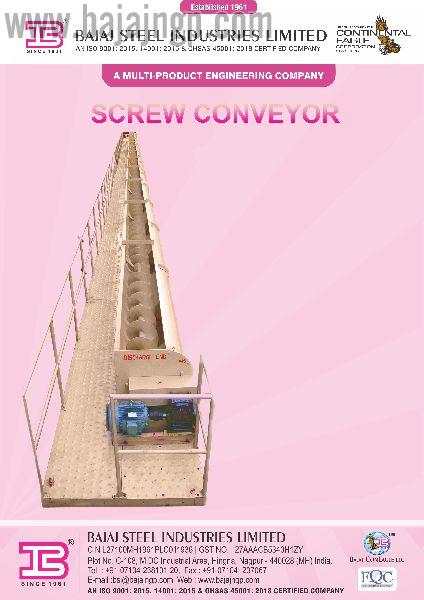

| Business Type | Manufacturer, Exporter, Supplier |

| Finishing | Powder Coated |

| Width | 10-20 Inch, 20-30 Inch, 30-40 Inch |

| Machine Weight | Customised |

| Rated Power | 1-3 KW, 3-5 KW, 5-7 KW, 7-9 KW, 9-12 KW |

| Packaging Type | Wooden Box |

| Loading Capacity | 5-10 Kg, 10-15 Kg |

| Usage | Moving Goods |

| Specialities | Vibration Free, Unbreakable, Scratch Proof, Long Life, Heat Resistant, Excellent Quality, Corrosion Proof |

| Dimension (LxWxH) | Customised |

| Type | Flexible Screw Conveyor |

| Brand Name | Bajaj |

| Material | MS |

| Shape | Customised |

| Certification | ISO 9001:2008 |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Driven Type | Motor |

| Phase | Customised |

| Country of Origin | India |

| Operating Mode | Automatic |

| Corrosion Resistance | Yes |

| Speed Adjustable | Yes |

| Machine Material | Mild Steel |

| Rated Current | Customised |

| Frequency | Customised |

| Motor Power | Customised |

| Technique | Customised |

| Accuracy | Customised |

| After-Sales Service Provided | Yes |

| Noise Level | Customised |

| Operating Speed | Customised |

| Roller Diameter | Customised |

| Conveyor Height | Customised |

| Back Length | Customised |

| Trough | Customised |

| Flight Thickness | Customised |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Features:

- Quality tested

- Precisely engineered

- Easy to install

- Robust Construction

- Long life

- Maintenance free

- Uniform and adequate feeding at all points

- Ease of use

- Protects fiber quality

- Made with superior technical know how

Applications:

- Food processing

- Pulp and paper

- Stone, Glass, and Concrete

- Environmental

- Petroleum Refining

- Wood Products

- Chemicals

- Rubber and Plastics

- Primary Metals

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Type | Cotton Seed Cleaner |

| Certification | ISO 9001:2008 |

| Application | Seed Cleaning |

| Weight | Customised |

| Color | Tan |

| Voltage | 380V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | Customised |

| Production Capacity | Customised |

| Warranty | 1 Year |

| Drivin Type | Electric |

| Country of Origin | India |

| Brand Name | Bajaj |

| Capacity | Customised |

| After-Sales Service Provided | Yes |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Features :

- Consistent and uniform opening and feeding

- Higher productivity

- Reduced manpower cost

- Improves the quality of lint

- Lesser trash content in raw cotton

- Lesser contamination of seed cotton

- Robust construction

- Uniform and adequate feeding at all points

- Optimizes ginning performance

- Easy of use

- Reduced manpower costs

- Made with superior technical know how

- Easily accommodated in existing systems

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

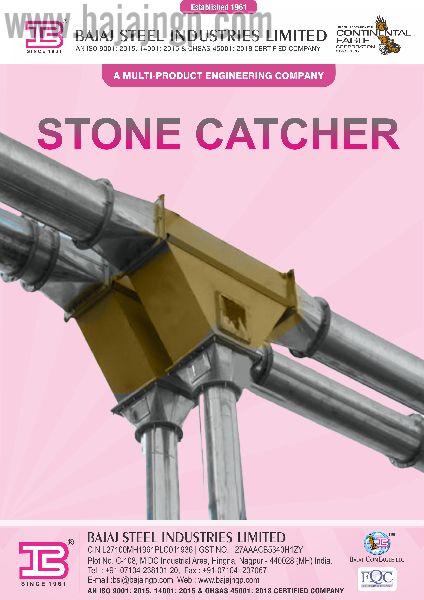

| Size | Customised |

| Type | Dust Remover |

| Material | STEEL |

| Shape | Customised |

| Thickness | Customised |

| Application | Stone Removal |

| Color | Tan |

| Feature | Durable, Easy Cleaning, Eco Friendly, Good Quality |

| Pattern | Plain |

| Packaging Type | Customised |

| Country of Origin | India |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Features & Benefits :

- Available in different sizes.

- Separate rocks, green bolls and any other heavy objects in the cotton seed.

- Efficient removal of stones, rocks, green bolls and other foreign particles without considerable pressure loss.

- Air Tight trap door prevents any pressure loss.

- Gravity removal of heavy foreign particles, stones, rocks etc.

- Reduces trash percentage in cotton.

- No transmission elements needed and hence the operation cost is minimum.

- Ease of use

- Maintenance free

- Robust Construction

- Protects fibre quality and strength

- Made with superior technical know how

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Size | Customised |

| Type | STEEL |

| Material | Natural Stone |

| Shape | Customised |

| Color | Tan |

| Feature | Durable, Easy To Clean |

| Pattern | Plain |

| Condition | New |

| Finishing | Polished |

| Height | Customised |

| Country of Origin | India |

| Capacity / hour (Avg) | 10,000 Kgs |

| Feeding System | Belt Conveyor |

| Width | 1015 mm |

| Length | 1150 mm |

| Payment Terms | D/A |

| Delivery Time | 30 Days |

Preferred Buyer From

| Location | Worldwide |

Salient Features :

- Virtually 100% stones are removed from seed cotton

- Eliminates fire risk in ginning

- Ease of use

- Maintenance free

- Robust Construction

- Protects fibre quality and strength

- Made with superior technical know how

- Hot air application for drying of cotton in case of need

- Enhances life of ginning parts.

- Enhances ease of ginning, resulting in high productivity.

- Reduces trash percentage in cotton.

- Can be used for moisture regulation in the raw cotton before going for ginning.

- No transmission elements needed and hence the operation cost is minimum.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

The Suction –Command System takes the worry out of finding dependable labour for suction feeding seed cotton from your trailers or modules. The standard system consists of two lanes independent suction lanes. Bajaj’s Suction – Command System can be designed to meet your individual needs from one to four suction lanes.

Unlimited directional control is smooth and easy. The steel carriage assembly and the high strength aluminium telescopes are very responsive to the operator’s controls.

Swing Momentum is always under control by the operator. The Suction Command operator cab is a clean , comfortable environment.

6 MAJOR DESIGN FEATURES

Engineered for Strength with Less Weight.

Stronger design in critical areas, yet total weight saved reduces wear and strain on track rails and entire structure.

Thick Walled Aluminium Telescopes

Stronger Tubes with less weight give better control and put less stress on the swing mechanism.

Flexible Swivel Sleeve

A positive, air tight fit provides efficient operation and requires minimum maintenance.

Large Radius Elbows

Choking is virtually eliminated

Four Rubber Covered Carriage Wheels

All wheels are powered delivering positive traction. Traverse travel is straight… no binding.

Industrial Grade Hydraulic Cylinders

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Shown with 24” vacuum – Vacuum, ductwork, and supports are not included with the Super III

The Super III is unequalled for bulk removal of sticks, hulls and leaves from machine picked or stripped cotton. Cotton entering the machine is directed to two large extracting cylinders and a third saw cylinder cleans and reclaims excess cotton from the main cleaning cylinders.

The efficient extraction of foreign matter greatly reduces the wear and damage to other ginning equipment.

The Super III is the practical, performance proven machine for better cleaning at high capacity and producing quality sample on all types of cotton.

The Super III installed in the gining plant assures more effective and efficient operation of the machinery processes that follow. it is designed to operate at capacities equal to the overall installation requirements.

Profit – Making Features :

- Super III sling-off action assures no restriction of cotton flow for high capacity.

- Super III can be installed in existing gin outfit with minimum engineering and rearrangement.

- Continental Eagle precision manufactured temperhardended channel saws on dynamically balanced cylinders.

- Wire brushes set cotton on saw cylinders.

- Bar grids designed for more effective stick removal-easily adjusted to saw.

- High speed doffing cylinders remove cotton from 16″ saw cleaning cylinders.

- Lower saw cylinder reclaims cotton-cleans as effectively as upper cylinders.

- Two large doors on back of Super III provide easy access for maintenance.

- Metal doffers for long life.

- Minimum maintenance.

- Built-in by-pass for cleanly picked cotton.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Benefits & Features :

- Robust construction longer life.

- Form an integral part of seed cotton distribution system to gins.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Programmed to ensure continuous feeding to pre cleaner, belt conveyor or any other system for greater productivity.

- Variable feed rates for specific requirements.

- Supplied with high quality electrical accesories and dust proof sensors for efficient performance.

- Uniform and adequate feeding

- Optimizes ginning performance

- Made with superior technical know how

- Robust construction

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

Benefits & Features :

- Robust construction; longer life.

- Form an integral part of seed cotton distribution system to gins.

- Considerable saving in labour cost.

- Available in different models for specific requirements.

- Programmed to ensure continuous feeding to gins for greater productivity.

- Variable feed rates for specific requirements.

- Supplied with high quality electrical accesories and dust proof sensors for efficient performance.

- Optimizes ginning performance

- Made with superior technical know how

- Robust construction

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

The bajaj-cec vertical flow driertm dries better by doing the right thing at the right time. every ginner knows that cotton can’t be cleaned until it is dried and it cant be dried until it is loosened and fluffed so that hot air can penetrate to every fiber. this drier maximizes these processes.

Seed cotton enters the bajaj-cec vertical flow driertm matted, moist and trashy. as the seed cotton enters, it falls onto the first directional cylinder arranged to break up wads and create a loosened stream of seed cotton. the loosened seed cotton slides down baffles made of long thin fingers, with air spacing between each finger, to another cylinder which throws the cotton in another direction. this alternating action is repeated five more times. it is this action that further creates and maintains a stream of seed cotton, increasing the exposure of the heated air to every fiber, maximizing both effectiveness and efficiency.

There are no shelves, screens or grids to roll and twist the cotton before it is dried. the opening and fluffing by the directional cylinders causes the locks of cotton to literally spring open to increase the drying action of the drier.

- The directional cylinders are powered by a 10 hp (7.46 kw) motor*.

- The proven cotton drier that will make the difference.

- Talk to a ginner that has one!

- The bajaj-cec vertical flow drier was designed to reduce fan power and heater fuel consumption while increasing air flow and drying capability as well as preserving fiber quality

- Pressure drop within the drier never exceeds 2″ of water, compared to 12″ for many tower driers. less fan energy is required to move the air through the machine

- High efficiency means less heat and better fiber quality preservation. customers have reported processing more than 50 bales per hour with a single vertical flow drier with seed cotton moisture exceeding 18%.

Features :

- No shelves, screens or grids to roll and twist cotton.

- Directional cylinders break up wads and direct cotton to other cylinders along fingered baffles for even heat distribution.

- Fluffed cotton allows for uniformed drying of every fiber.

- Maximizes moisture removal with minimal heat applied.

- Dramatically improves first stage cleaning machinery efficiency by loosening and fluffing seed cotton.